Multi-Tower Automated Storage Systems

Not all automated storage needs are created equal. A small tool-and-die shop has different requirements than a high-volume automotive supplier. That’s why modern tower-type automated warehouse systems come in three primary configurations—mono, double, and multi-tower—each offering distinct advantages in cost, capacity, and scalability.Understanding these options is crucial for making an informed investment that aligns with your current operations and future growth.

Not all automated storage needs are created equal. A small tool-and-die shop has different requirements than a high-volume automotive supplier. That’s why modern tower-type automated warehouse systems come in three primary configurations—mono, double, and multi-tower—each offering distinct advantages in cost, capacity, and scalability.

Understanding these options is crucial for making an informed investment that aligns with your current operations and future growth.

Mono Tower: Simplicity and Focus

The mono tower is a single-column system served by one dedicated lift. It’s ideal for businesses needing to automate storage for one primary material type—such as a mold storage application or a dedicated sheet metal buffer near a single machine.

Pros:

- Lower upfront cost

- Easy installation and maintenance

- Minimal footprint (as small as 2m x 2m)

- Perfect for pilot projects or departmental use

Best for: Job shops, R&D labs, or satellite workstations requiring localized automation.

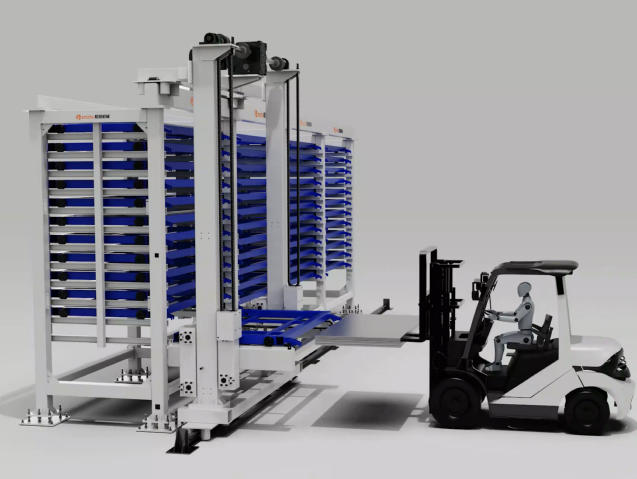

Double Tower: Balanced Efficiency

A double tower configuration features two vertical storage columns sharing one central lift mechanism, often with a horizontal transfer trolley that shuttles loads between sides. This design doubles storage capacity without doubling the mechanical components—offering excellent ROI.

Pros:

- 2x storage in ~1.5x the footprint of a mono tower

- Shared lift reduces energy and maintenance costs

- Enables segregation (e.g., raw vs. finished, steel vs. aluminum)

- Supports higher throughput with minimal added complexity

Best for: Mid-sized fabricators, electronics assemblers, or plants running dual-shift operations.

Multi-Tower: Enterprise-Grade Automation

For large facilities managing hundreds of SKUs or serving multiple production lines, the multi-tower system creates a fully integrated vertical warehouse. Multiple towers are networked via conveyors, AGVs, or rail-guided vehicles, all controlled by a central WMS.

Pros:

- Massive storage density (thousands of SKUs)

- Full FIFO/LIFO control and batch traceability

- Seamless integration with end-to-end production

- Scalable—add towers as demand grows

Best for: Automotive OEMs, aerospace manufacturers, or distribution centers requiring high-velocity, high-accuracy material flow.

Making the Right Choice

Consider these questions:

- What’s your average daily retrieval volume?

- Do you handle multiple material types or just one?

- Is floor space extremely limited?

- Do you plan to expand in the next 3–5 years?

A mono tower might suffice today—but if growth is imminent, designing for double or multi-tower compatibility from the start saves costly retrofits later.

Regardless of configuration, all tower systems share core benefits: space savings, labor reduction, enhanced safety, and digital readiness. By matching the right architecture to your operational profile, you unlock the full potential of automated vertical storage—today and tomorrow.

Factory

Hot Selling Machines

-

Heavy Duty Sheet Metal Storage Racks

Intelligent Production Line CNC Automated Storage Rack: Precision Meets Automation

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drawer-Style Sliding Sheet Metal Storage Rack – Efficient & Safe Material Handling

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Design for Steel Plate Storage with Heavy Duty Drawer Type Sheet Metal Rack Storage System

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Rack for Heavy Plates and Molds: Durable, Efficient Storage for Industrial Applications

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drive-In Pallet Rack Alternative: Space-Saving Drawer-Type Sheet Metal Storage with Automated Retrieval Compatibility

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Drawer Type Plate Shelves Warehouse Rack System for Industrial Metal Storage – 3-Ton Capacity per Layer

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Warehouse Storage System: Customizable Solutions for Metal Plate & Industrial Storage

Read moreRated 0 out of 5 -

Automated Storage Systems

Smart Fixed Profile Stereo Warehouse: Cost-Effective Automation for Small to Mid-Sized Fabrication Shops

Read moreRated 0 out of 5

Related products

Related products

-

Automation Sheet Metal Material Warehouse

Automatic Sheet Metal Storage & Retrieval System (AS/RS) – Automated Loading Unloading Racks

Read moreRated 0 out of 5 -

Automation Sheet Metal Material Warehouse

Metal Sheet Warehouse Rack Solution

Read moreRated 0 out of 5 -

Automation Sheet Metal Material Warehouse

Customized Steel Electric Telescopic Automatic Loading and Unloading System

Read moreRated 0 out of 5 -

Automation Sheet Metal Material Warehouse

Fully Automatic Vertical Profile Smart Storage Unit

Read moreRated 0 out of 5