Tower-type Automated Material Storage System

In the fast-paced world of metal processing, where efficiency, space optimization, and safety are paramount, the tower-type automated material storage system has emerged as a game-changing solution. Metal processing facilities often grapple with the challenge of storing heavy, bulky items such as sheet metal, bars, and tubes—materials that not only take up significant floor space but also pose risks during manual handling. This is where the tower-type automated material storage system steps in, redefining how metal processing businesses manage their inventory while boosting productivity and cutting operational costs.

Tower-type Automated Material Storage System: Revolutionizing Metal Processing Warehousing

In the fast-paced world of metal processing, where efficiency, space optimization, and safety are paramount, the tower-type automated material storage system has emerged as a game-changing solution. Metal processing facilities often grapple with the challenge of storing heavy, bulky items such as sheet metal, bars, and tubes—materials that not only take up significant floor space but also pose risks during manual handling. This is where the tower-type automated material storage system steps in, redefining how metal processing businesses manage their inventory while boosting productivity and cutting operational costs.

Understanding the Core of Tower-type Automated Material Storage Systems

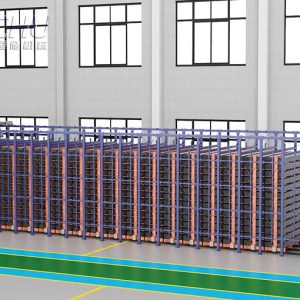

At its heart, a tower-type automated material storage system is a vertical storage solution designed to maximize space utilization by leveraging the height of a facility rather than just the floor area. Unlike traditional horizontal storage racks that require wide aisles for forklifts or manual access, these systems use automated lifts and carriers to store and retrieve materials with precision. This vertical approach is a game-changer for metal processing plants, where floor space is often at a premium due to large machinery like cutting and bending equipment.

One of the key advantages of this system is its ability to handle heavy loads—some configurations can store items weighing up to 5 tons per pallet. For metal processing businesses dealing with thick sheet metal or long metal profiles, this weight capacity is crucial. The system’s compartments are fully adjustable, allowing customization to fit different material dimensions. Whether it’s a 10-foot-long metal bar or a large sheet of aluminum, the compartments can be tailored to ensure a secure fit, reducing the risk of damage during storage or retrieval.

Space Efficiency: A Top Priority for Metal Processing Facilities

Space is a valuable resource in any metal processing facility. With large machines, workstations, and inventory, floor space can quickly become cramped, leading to inefficiencies and even safety hazards. The tower-type automated material storage system addresses this issue head-on by reducing the storage footprint by up to 50%. By moving storage vertically, facilities can free up valuable floor space for additional machinery, expanded production lines, or improved workflow layouts.

For example, consider a medium-sized metal processing plant that previously used horizontal racks to store sheet metal. These racks required 2,000 square feet of floor space, including wide aisles for forklifts. After installing a tower-type automated system, the same inventory was stored in just 1,000 square feet, with no need for large aisles. The freed-up space allowed the plant to add a new bending machine, increasing production capacity by 30% within months. This kind of space savings not only improves operational efficiency but also provides a competitive edge by enabling businesses to expand without relocating to a larger facility.

Automated Handling: Reducing Labor and Enhancing Safety

Manual handling of heavy metal materials is not only time-consuming but also dangerous. Workers risk strains, sprains, or more serious injuries when lifting or moving sheet metal, bars, or tubes. The tower-type automated material storage system eliminates most manual labor by using automated lifts, extractors (such as cranes, vacuum systems, or clamps), and carriers to move materials. This not only reduces the risk of workplace injuries but also speeds up the storage and retrieval process.

The automated handling process is seamless and precise. When a worker needs a specific piece of sheet metal for a cutting job, they simply input the request into the system’s control panel. The automated lift then moves to the correct compartment, retrieves the material using a specialized extractor (such as a vacuum clamp for sheet metal), and delivers it to an operator station at a comfortable working height. This eliminates the need for workers to climb ladders, use forklifts, or manually lift heavy items, reducing fatigue and improving overall productivity.

In addition to reducing labor costs, automated handling also minimizes the risk of material damage. Manual handling often leads to dents, scratches, or bending of metal materials, which can render them unusable or require costly rework. The automated system’s precise movements ensure that materials are handled gently and securely, reducing waste and saving businesses money on replacement or repair costs.

Ergonomics & Safety: Protecting Workers and Improving Morale

Ergonomics is a critical factor in any workplace, especially in metal processing where workers are often required to perform repetitive tasks or handle heavy loads. The tower-type automated material storage system is designed with ergonomics in mind, delivering materials to operator stations at a comfortable working height. This eliminates the need for workers to bend, stretch, or reach overhead to access materials, reducing the risk of musculoskeletal disorders (MSDs) such as back pain or shoulder injuries.

Furthermore, the system is equipped with advanced safety features to protect workers. Sensors are installed throughout the system to detect the presence of operators near moving parts, automatically pausing operations if a worker is in the danger zone. Emergency stop buttons are also easily accessible, allowing workers to halt the system immediately if an issue arises. These safety features not only protect workers but also improve morale, as employees feel valued and safe in their workplace. A safer work environment leads to lower absenteeism rates and higher employee retention, which in turn reduces recruitment and training costs for businesses.

Integration with ERP/WMS Systems: Real-Time Inventory Control

In today’s digital age, real-time inventory control is essential for metal processing businesses to meet customer demands and avoid stockouts. The tower-type automated material storage system seamlessly integrates with Enterprise Resource Planning (ERP) and Warehouse Management System (WMS) software, providing real-time data on inventory levels, location, and movement.

This integration allows businesses to track materials from the moment they arrive at the facility to when they are used in production or shipped to customers. For example, if a customer places an order for a specific type of sheet metal, the ERP system can quickly check the inventory levels in the automated storage system and confirm if the material is available. If it is, the WMS can automatically trigger the retrieval process, ensuring that the material is delivered to the production line on time. This real-time visibility eliminates the need for manual inventory counts, which are time-consuming and prone to errors. It also helps businesses optimize their inventory levels, reducing excess stock and freeing up capital that can be invested in other areas of the business.

Flexibility and Scalability: Adapting to Changing Business Needs

Metal processing businesses often face changing demands, whether it’s a new product line, an increase in order volume, or a shift in the types of materials they handle. The tower-type automated material storage system is designed to be flexible and scalable, allowing businesses to adapt to these changes without significant investments in new equipment.

The system’s modular design means that additional towers can be added as needed. For example, a small metal processing business that starts with a single mono tower (a single tower with one lift) can expand to a double tower (two towers served by one lift, often with a transfer trolley) or a multi-tower system (multiple towers forming a large, modular warehouse) as its inventory grows. This scalability ensures that the system can grow with the business, avoiding the need to replace the entire system when more storage space is required.

Additionally, the system’s ability to store a wide range of heavy goods—from sheet metal and rods to molds and even large tools—makes it a versatile solution for metal processing facilities. Whether a business is processing steel, aluminum, or copper, the system can be customized to handle the specific materials and dimensions required. This flexibility allows businesses to diversify their product offerings without worrying about how to store new materials.

Real-World Success Story: How a Metal Processing Plant Benefited from the System

To illustrate the impact of the tower-type automated material storage system, let’s look at the case of a large metal processing plant in the Midwest. Prior to installing the system, the plant struggled with several issues: limited floor space, high labor costs due to manual handling, frequent material damage, and inaccurate inventory counts. The plant used traditional horizontal racks to store sheet metal and metal bars, which took up 3,500 square feet of floor space. Workers had to use forklifts to access materials, leading to long wait times and a high risk of accidents. Inventory counts were done manually once a month, often resulting in discrepancies that led to stockouts or excess inventory.

After researching various storage solutions, the plant decided to invest in a multi-tower automated material storage system. The system was customized to fit the plant’s specific needs, with compartments designed to hold sheet metal of various sizes and metal bars up to 15 feet long. The system was also integrated with the plant’s existing ERP and WMS systems, providing real-time inventory visibility.

The results were impressive. Within the first six months, the plant reduced its storage footprint by 55%, freeing up 1,925 square feet of floor space. This space was used to install two new cutting machines, increasing production capacity by 40%. Labor costs related to material handling decreased by 30% because fewer workers were needed to move materials. Material damage dropped by 70%, as the automated system handled materials gently and precisely. Real-time inventory data eliminated stockouts and reduced excess inventory by 25%, freeing up $150,000 in capital.

The plant’s management reported that the system not only improved operational efficiency but also enhanced employee satisfaction. Workers no longer had to perform strenuous manual labor, and the reduced risk of accidents made the workplace safer. Customer satisfaction also increased, as the plant was able to fulfill orders faster and with fewer errors.

Why Choose a Tower-type Automated Material Storage System for Your Metal Processing Facility?

If you’re running a metal processing business, the tower-type automated material storage system offers a wide range of benefits that can transform your operations. From maximizing space efficiency and reducing labor costs to enhancing safety and providing real-time inventory control, this system is designed to address the unique challenges faced by metal processing facilities.

Whether you’re a small shop looking to expand or a large plant aiming to optimize your workflow, the system’s flexibility and scalability make it a long-term investment. It not only improves your current operations but also positions your business for growth in the future. By reducing waste, improving productivity, and enhancing safety, the tower-type automated material storage system can help you stay competitive in the ever-evolving metal processing industry.

In conclusion, the tower-type automated material storage system is more than just a storage solution—it’s a strategic investment that can improve every aspect of your metal processing business. From space savings and automated handling to real-time inventory control and scalability, this system has the potential to revolutionize how you manage your inventory and operate your facility. If you’re ready to take your metal processing business to the next level, it’s time to consider implementing a tower-type automated material storage system.

Factory

Hot Selling Machines

-

Heavy Duty Sheet Metal Storage Racks

Intelligent Production Line CNC Automated Storage Rack: Precision Meets Automation

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drawer-Style Sliding Sheet Metal Storage Rack – Efficient & Safe Material Handling

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Design for Steel Plate Storage with Heavy Duty Drawer Type Sheet Metal Rack Storage System

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Rack for Heavy Plates and Molds: Durable, Efficient Storage for Industrial Applications

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drive-In Pallet Rack Alternative: Space-Saving Drawer-Type Sheet Metal Storage with Automated Retrieval Compatibility

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Drawer Type Plate Shelves Warehouse Rack System for Industrial Metal Storage – 3-Ton Capacity per Layer

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Warehouse Storage System: Customizable Solutions for Metal Plate & Industrial Storage

Read moreRated 0 out of 5 -

Automated Storage Systems

Smart Fixed Profile Stereo Warehouse: Cost-Effective Automation for Small to Mid-Sized Fabrication Shops

Read moreRated 0 out of 5

Related products

Related products

-

Automated Storage Systems

Intelligent Fixed Profile Three-Dimensional Material Storage: Enhancing Traceability and Safety for Critical Industries

Read moreRated 0 out of 5 -

Automated Storage Systems

Automated Storage Rack System for Sheet Metal – Cost-Effective and Flexible Solution for Medium and Small-Scale Enterprises

Read moreRated 0 out of 5 -

Automated Storage Systems

Top-mounted Mobile Metal Tube Rack Storage System

Read moreRated 0 out of 5