The metal processing industry operates in a high-stakes environment where every inefficiency can translate to lost profits, delayed orders, and compromised safety. For decades, metal processors have struggled with outdated storage solutions that fail to keep up with the demands of heavy, bulky materials like sheet metal, steel bars, and metal tubes. These traditional methods—such as manual shelving and horizontal racks—consume excessive floor space, rely on labor-intensive handling, and expose workers to unnecessary risks. Today, a revolutionary solution has emerged to address these pain points: the tower-type automated material storage system. This innovative technology is not just a storage upgrade; it’s a complete transformation of how metal processing facilities manage their inventory, streamline operations, and protect their most valuable assets—their workers and their materials.

The Fundamental Shift: From Horizontal to Vertical Storage

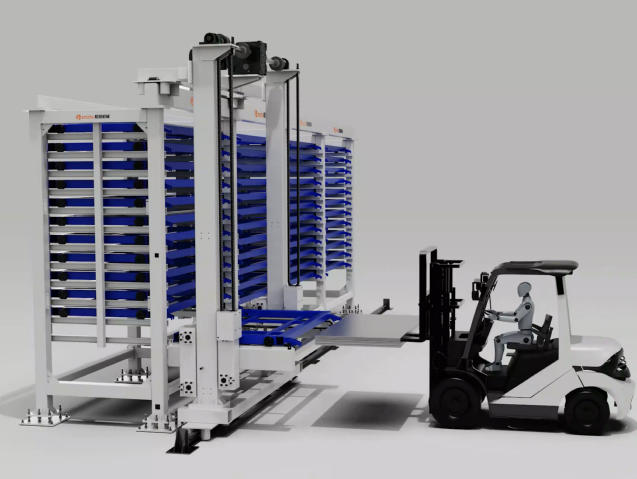

The core innovation of the tower-type automated material storage system lies in its rejection of the traditional “horizontal-first” approach to warehousing. Instead of spreading inventory across large swaths of floor space, this system leverages the vertical dimension of a facility—turning unused ceiling height into valuable storage real estate. For metal processing plants, where floor space is often occupied by large machinery (such as laser cutters, bending presses, and welding stations), this vertical shift is a game-changer.

Consider the physical constraints of a typical medium-sized metal processing facility. A plant that uses horizontal racks to store 500 sheets of steel (each measuring 4×8 feet) might require 1,800 square feet of floor space, including 6-foot-wide aisles for forklifts to navigate. In contrast, a tower-type automated system can store the same 500 sheets in just 800 square feet—cutting the storage footprint by more than 50%. This freed-up space isn’t just “extra room”; it’s an opportunity to add a new production line, expand a work area, or even reduce the facility’s overall size (and associated rent or mortgage costs).

But the benefits of vertical storage go beyond space savings. The system’s design allows for precise compartmentalization, with each section customized to fit the exact dimensions of the materials being stored. For example, a facility that handles both 10-foot-long steel bars and 3-foot-wide aluminum sheets can adjust the tower’s compartments to accommodate both—no more wasting space on one-size-fits-all racks. This customization also reduces the risk of material damage, as each item is securely held in place, preventing shifting, bending, or scratching during storage.

Automated Handling: Eliminating Labor Risks and Delays

Manual handling of heavy metal materials is one of the biggest challenges in the metal processing industry. A single sheet of 10-gauge steel can weigh up to 150 pounds, and a steel bar of 20 feet can exceed 1,000 pounds. Lifting, moving, and positioning these materials manually requires significant physical effort, leading to a high risk of musculoskeletal injuries (MSDs) such as herniated discs, shoulder strains, and carpal tunnel syndrome. According to the Bureau of Labor Statistics (BLS), the metal manufacturing industry has one of the highest rates of workplace injuries related to manual material handling—costing businesses an average of $40,000 per injury in medical bills, lost productivity, and workers’ compensation claims.

The tower-type automated material storage system eliminates these risks by replacing manual labor with advanced automated handling technology. At the heart of the system are automated lifts (also known as “stacker cranes”) and specialized extractors—each designed to handle specific types of metal materials. For sheet metal, vacuum extractors use powerful suction to lift and move sheets without leaving marks or causing damage. For heavy steel bars, hydraulic clamps provide a secure grip, ensuring stability during transport. For irregularly shaped items like metal molds, custom-designed grippers adapt to the material’s unique contours.

The process of retrieving materials is seamless and efficient. When a worker needs a specific material for a production job, they simply input the request into the system’s user-friendly control panel (which can be accessed via a desktop computer, tablet, or even a mobile device). The system then uses a combination of sensors and software to locate the material in the tower, send the automated lift to the correct compartment, and retrieve the item. Within minutes, the material is delivered to a designated operator station at a comfortable working height—typically between 30 and 40 inches off the ground. This eliminates the need for workers to climb ladders, operate forklifts in tight spaces, or manually lift heavy items, reducing fatigue and improving overall productivity.

For example, a metal processing plant in Ohio that previously relied on two workers and a forklift to retrieve sheet metal reported that the process took an average of 12 minutes per sheet. After installing a tower-type automated system, the retrieval time dropped to just 2 minutes per sheet—a 83% reduction. This not only speeded up production but also allowed the plant to reassign the two workers to more skilled tasks, such as quality control and machine operation, improving overall operational efficiency.

Safety First: Advanced Features to Protect Workers and Materials

Safety is a top priority in any metal processing facility, and the tower-type automated material storage system is designed with this in mind. The system includes a range of advanced safety features that go far beyond what traditional storage solutions can offer.

One of the most critical safety features is the system’s sensor-based collision avoidance technology. The automated lifts are equipped with infrared sensors and cameras that constantly scan the surrounding area for obstacles—including workers, other machinery, and debris. If a sensor detects an obstacle, the lift immediately slows down or stops, preventing collisions. Additionally, the system’s compartments are equipped with pressure sensors that ensure materials are securely stored; if a material is not properly positioned, the system alerts operators and prevents the lift from moving, reducing the risk of items falling during storage or retrieval.

Another key safety feature is the system’s emergency stop (E-stop) functionality. E-stop buttons are strategically placed throughout the facility—on the control panel, near the operator stations, and along the perimeter of the tower. If an emergency occurs (such as a material shift or a worker entering a restricted area), any employee can press an E-stop button to halt all system operations immediately. The system also includes audio and visual alarms that activate in case of a malfunction, alerting workers to potential issues before they become hazards.

In addition to protecting workers, the system’s safety features also protect materials. Metal materials are often expensive, and damage during storage or handling can result in significant financial losses. The system’s gentle handling technology—such as soft-closing compartment doors and shock-absorbing extractors—ensures that materials are not dented, scratched, or bent. For example, a stainless steel processing plant in Michigan that produces custom parts for the food and beverage industry reported that material damage decreased by 90% after installing the system. This not only saved the plant money on replacement materials but also improved customer satisfaction, as fewer orders were delayed due to damaged parts.

Seamless Integration with ERP and WMS Systems: Real-Time Inventory Control

In today’s digital age, effective inventory management requires more than just storing materials—it requires real-time visibility into inventory levels, movement, and usage. Traditional storage systems rely on manual inventory counts, which are time-consuming, prone to errors, and provide only a snapshot of inventory at a specific point in time. This can lead to stockouts (when materials are needed but not available) or overstocking (when materials are stored unnecessarily, tying up capital).

The tower-type automated material storage system solves this problem by seamlessly integrating with Enterprise Resource Planning (ERP) and Warehouse Management System (WMS) software. This integration allows for real-time tracking of every material in the system, from the moment it arrives at the facility to the moment it is used in production or shipped to a customer.

Here’s how it works: When a new shipment of metal materials arrives at the facility, each item is labeled with a unique barcode or RFID tag. The tag contains information such as the material type, dimensions, weight, and batch number. The item is then scanned into the WMS, which automatically assigns it to an available compartment in the tower. The WMS updates the ERP system in real time, so managers can immediately see that the material is in stock and available for use.

When a worker requests a material for production, the request is sent from the ERP system to the WMS, which triggers the automated retrieval process. Once the material is delivered to the operator station, the WMS updates the inventory level, marking the material as “in use.” If the material is not fully used (e.g., a partial sheet of metal), the remaining portion is scanned back into the system, and the WMS updates the inventory level accordingly.

This real-time integration provides a range of benefits for metal processing facilities. For one, it eliminates the need for manual inventory counts, which can take days to complete and often result in errors. A plant in Indiana that previously spent 40 hours per month on manual inventory counts reported that the automated system reduced this time to just 2 hours per month—a 95% reduction. Additionally, real-time inventory data allows managers to make more informed decisions about purchasing and production. For example, if the ERP system shows that a certain type of steel is running low, managers can order more before a stockout occurs, preventing production delays.

The integration also improves traceability—a critical requirement for many metal processing facilities, especially those that supply industries such as aerospace, automotive, and medical devices. These industries require detailed records of where materials come from, how they are stored, and when they are used. With the tower-type automated system, every step of the material’s journey is recorded in the ERP and WMS systems, making it easy to provide auditors with the documentation they need to comply with industry regulations.

Flexibility and Scalability: Growing with Your Business

The metal processing industry is constantly evolving, with businesses facing changing customer demands, new product lines, and fluctuating order volumes. A storage system that works today may not work tomorrow, which is why flexibility and scalability are key considerations for any facility.

The tower-type automated material storage system is designed to be both flexible and scalable, allowing it to adapt to the changing needs of a business. The system’s modular design means that additional towers can be added as inventory levels grow. For example, a small metal processing shop that starts with a single mono tower (a single tower with one lift) can easily add a second tower (known as a double tower) as its customer base expands. A double tower system uses a single lift to serve two towers, often with a transfer trolley to move materials between towers, doubling storage capacity without doubling the footprint. For larger facilities, multi-tower systems can be installed, with multiple towers connected by a network of lifts and conveyors, creating a fully automated warehouse that can handle thousands of materials.

The system’s flexibility also extends to the types of materials it can store. While it is ideal for heavy metal materials like sheet metal, steel bars, and tubes, it can also be customized to store other items, such as metal molds, tools, and even finished products. For example, a plant that produces custom metal parts for the construction industry uses its tower system to store both raw materials (steel bars) and finished parts (metal brackets), eliminating the need for separate storage areas.

Another aspect of the system’s flexibility is its ability to adapt to different facility layouts. Unlike traditional storage systems, which require a fixed layout, the tower-type system can be installed in existing facilities, even those with irregular shapes or limited space. The towers can be placed along walls, in corners, or even in the middle of a facility, depending on the available space and the facility’s workflow. This makes it a great option for businesses that want to upgrade their storage system without undergoing a full facility renovation.

Real-World Results: A Case Study from the Midwest

To truly understand the impact of the tower-type automated material storage system, let’s look at the experience of a large metal processing plant in Illinois. The plant specializes in producing sheet metal components for the automotive industry, and prior to installing the system, it faced a range of challenges:

- Space Constraints: The plant’s floor space was fully occupied by horizontal racks and production machinery, leaving no room for expansion.

- High Labor Costs: The plant employed 10 workers dedicated to material handling, including operating forklifts and manually moving sheet metal.

- Material Damage: Approximately 15% of sheet metal was damaged during storage or handling, resulting in $120,000 in annual losses.

- Inventory Issues: Manual inventory counts led to frequent stockouts, causing production delays that cost the plant $50,000 per month in lost orders.

After researching various storage solutions, the plant decided to invest in a multi-tower automated material storage system. The system included three towers, each with customized compartments for sheet metal of various sizes, and was integrated with the plant’s existing ERP and WMS systems.

The results were transformative:

- Space Savings: The system reduced the plant’s storage footprint by 60%, freeing up 2,400 square feet of floor space. The plant used this space to add a new laser cutting machine, increasing production capacity by 35%.

- Labor Cost Reduction: The automated handling system eliminated the need for 8 of the 10 material handling workers. The remaining two workers were reassigned to quality control roles, improving the plant’s product quality.

- Material Damage Reduction: Material damage dropped from 15% to less than 2%, saving the plant $105,600 in annual replacement costs.

- Inventory Improvement: Real-time inventory tracking eliminated stockouts, reducing production delays by 100% and recovering $600,000 in annual lost orders.

In addition to these financial benefits, the plant also reported improved employee satisfaction. Workers no longer had to perform strenuous manual labor, and the reduced risk of injuries made the workplace safer. The plant’s safety record improved significantly, with no material handling-related injuries reported in the first year after installing the system.

Why Your Metal Processing Facility Needs This System

If you’re running a metal processing facility, you know that every decision you make affects your bottom line. The tower-type automated material storage system is not just a storage solution—it’s an investment in your facility’s efficiency, safety, and long-term growth. Here are just a few of the reasons why this system is a must-have for any modern metal processing plant:

- Maximize Space Utilization: By leveraging vertical space, the system frees up floor space for production, expansion, or other critical uses.

- Reduce Labor Costs: Automated handling eliminates the need for manual material handling, allowing you to reassign workers to more valuable tasks.

- Improve Safety: Advanced safety features protect workers from injuries and materials from damage, reducing costs associated with accidents and replacements.

- Enhance Inventory Control: Real-time integration with ERP and WMS systems provides accurate, up-to-date inventory data, preventing stockouts and overstocking.

- Adapt to Change: The system’s flexibility and scalability allow it to grow with your business, ensuring it remains a valuable asset for years to come.

Conclusion

The metal processing industry is facing unprecedented challenges—from increasing customer demands to rising labor costs. To stay competitive, facilities need to embrace innovative solutions that streamline operations, improve safety, and reduce costs. The tower-type automated material storage system is one such solution. By transforming how you store and handle materials, this system can help you maximize space, reduce labor costs, improve safety, and gain real-time control over your inventory.

Whether you’re a small shop looking to expand or a large plant aiming to optimize your operations, the tower-type automated material storage system has the potential to revolutionize your business. It’s not just a storage upgrade—it’s a step toward a more efficient, safe, and profitable future. If you’re ready to take your metal processing facility to the next level, it’s time to invest in a tower-type automated material storage system.