Heavy Duty Steel Plate Manipulator

Rather than force you into a single compromise configuration, Herochu offers three distinct performance tiers, each engineered around specific material thickness and weight parameters. The entry-level variant handles plates from 1mm to 8mm thick, with a maximum sheet format of 3,000mm x 1,500mm and a 300-kilogram gross weight limit. This configuration dominates in electrical cabinet manufacturing, where operators constantly feed galvanized steel blanks of varying thicknesses to CNC punching stations.

Eliminate the Gap Between Material Storage and Machine Loading: Herochu Heavy Duty Steel Plate Manipulator

Every fabricator knows the bottleneck isn’t in the cutting speed of your new fiber laser or the stroke rate of your press brake. The real productivity drain happens in those seven to twelve minutes between jobs when your operator wrestles a 300-kilogram steel plate from a stack, maneuvers it across the shop floor, and precisely positions it on the machine bed. Multiply that by fifteen changeovers per shift, factor in the injury risk and occasional sheet damage, and suddenly your quarter-million-dollar machine spends more time idle than profitable. Herochu’s Heavy Duty Steel Plate Manipulator, beginning at $6,999, dismantles this constraint entirely by transforming material handling from a manual chore into a fluid, one-operator, thirty-second workflow.

Three Weight Classes, One Unified Architecture

Rather than force you into a single compromise configuration, Herochu offers three distinct performance tiers, each engineered around specific material thickness and weight parameters. The entry-level variant handles plates from 1mm to 8mm thick, with a maximum sheet format of 3,000mm x 1,500mm and a 300-kilogram gross weight limit. This configuration dominates in electrical cabinet manufacturing, where operators constantly feed galvanized steel blanks of varying thicknesses to CNC punching stations.

Mid-range units step up to 1-14mm material thickness while maintaining the same 3,000mm x 1,500mm envelope, but boost load capacity to 500 kilograms. Kitchen equipment manufacturers gravitate toward this model; the increased capacity manages the dense stainless steel plates common in commercial oven housings and ventilation hoods without over-specifying for weight they’ll never use.

The heavy-duty configuration—the one that genuinely earns its name—accepts plates from 1mm to 20mm thick, supports the full 3,000mm x 1,500mm format, and confidently manipulates loads up to 1,000 kilograms. This is the specification metal fabrication shops choose when they’re feeding armor plate to plasma cutters or positioning thick mild steel for large-format press brake work. All three variants share identical minimum sheet dimensions of 1,250mm x 1,250mm, ensuring even modestly-sized blanks receive secure, predictable handling.

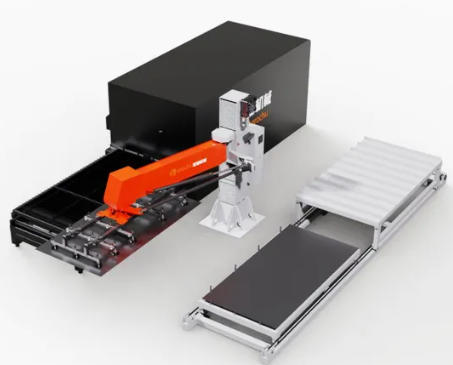

The Anatomy of a Servo Swing Arm

What appears as a simple articulated arm actually integrates multiple coordinated subsystems. The robot body itself uses a planetary gear reduction system on each axis, delivering positioning accuracy within ±1mm without the backlash that plagues worm-gear drives. This matters when you’re aligning a half-ton plate with a laser cutter’s 3mm-wide slats; imprecision means dropped sheets, damaged machine beds, and operator intervention.

The high-torque servo synchronous lifting mechanism operates on a dual-rail, four-carriage architecture. Unlike chain-hoist systems that introduce sway and bounce during acceleration, this screw-driven lift maintains parallel alignment throughout the vertical stroke. The servo motor’s torque mode ensures the arm holds position even during power fluctuations—no drift, no settling, no unexpected descent.

Horizontal movement relies on servo arm positioning transmission with a rack-and-pinion drive. The pinion gear meshes directly with a ground steel rack embedded in the main beam, eliminating the stretching and wear that eventually degrade belt-driven systems. You’ll replace suction cups long before you service the transmission.

Suction Cup Array: Where Physics Meets Practicality

The manipulator’s business end features multiple heavy-duty oil-resistant suction cups, each individually valved. This isn’t about redundancy; it’s about adaptability. When handling a narrow 1,250mm blank, you deactivate outer cups to concentrate vacuum force on the material footprint. For full-width sheets, every cup engages, distributing the load across six or more vacuum zones.

Each cup includes a mechanical check valve that isolates it from the system if it encounters a hole or cutout in the sheet. Without this feature, one exposed cup would bleed vacuum and drop the entire load—an expensive lesson many shops learn the hard way with cheaper manipulators. The SNS pneumatic system maintains constant vacuum monitoring; if pressure drops below 80% of full hold, the control system triggers audible alarms and prevents horizontal movement until the operator acknowledges the fault.

Omron CNC Control: Familiarity Breeds Efficiency

Herochu deliberately chose an Omron CNC control system rather than developing proprietary software. Why? Because most fabricators already have Omron PLCs managing their press brakes and lasers. The programming syntax, troubleshooting procedures, and spare parts inventory transfer seamlessly. Your maintenance team doesn’t need specialized training; they apply existing knowledge to diagnose I/O issues, modify positioning routines, or adjust acceleration profiles.

The control interface displays real-time torque loads, position feedback, and vacuum status for each axis. When an operator calls technical support, they can read actual diagnostics over the phone rather than resorting to vague descriptions. This accelerates remote troubleshooting and minimizes downtime.

Safety Engineering, Not Safety Theater

Emergency stop buttons punctuate the system—on the main control pendant, at the machine interface, and on a wireless remote that stays with the operator. But E-stops are table stakes. The automatic braking system engages within 50 milliseconds of power loss, locking the arm in place using spring-applied, electrically-released brakes on both vertical and horizontal axes. A power failure mid-cycle doesn’t result in a catastrophic drop; it results in a controlled stop that holds position until power restores or manual release procedures activate.

The manipulator’s modular assembly structure contributes to safety during installation and reconfiguration. No single module exceeds 80 kilograms, allowing two technicians to assemble the system without hiring a mobile crane for rigging. This becomes critical when you need to relocate the unit to support a new machine layout—disassembly takes three hours, transport, and reassembly in another four, versus a full day with welded-frame alternatives.

Where This Equipment Earns Its Keep

In kitchenware manufacturing, the manipulator feeds stainless steel blanks to hydraulic presses forming sink basins. The oil-resistant suction cups maintain grip even when blanks arrive coated in protective lamination oil. The 500-kilogram capacity variant handles the thick 304-grade stainless used in commercial dish tables, while the adjustable cup configuration manages smaller 1,250mm blanks for residential range hoods without forcing operators to change end-effectors.

Electrical cabinet manufacturers face a different challenge: their 1.5mm and 2mm mild steel sheets arrive fiber-laser cut with intricate patterns of ventilation holes and cable knockouts. The individual cup shutoff valves become essential here, allowing the manipulator to bridge cutouts without losing vacuum. The Omron control integrates directly with the punching machine’s PLC, creating a handshake protocol that prevents the manipulator from entering the work envelope until the press brake ram fully retracts and locks.

General metal fabrication shops purchase the 1,000-kilogram variant for its versatility. One shift, it’s positioning 10mm plate for a plasma cutting table; the next, it’s feeding 3mm aluminum to a CNC router. The servo system’s programmable memory stores position profiles for each machine—select “Laser 1” on the pendant, and the arm automatically recalls the precise pickup height, travel path, and deposit coordinates. Switch to “Press Brake B,” and it adjusts for the lower bed height and narrower material window.

Quantifying the Productivity Step Change

Let’s run numbers for a typical scenario: a shop processing 2mm mild steel blanks on a turret punch, averaging ten material changes per eight-hour shift. Manual handling with a forklift and two operators consumes eight minutes per change—that’s 80 minutes daily of non-value-added activity. At a blended labor rate of $50/hour, you’re burning $66.67 per shift, or $16,667 annually, just moving material.

The Herochu manipulator reduces changeover to 90 seconds, including positioning and vacuum confirmation. Ten changes now consume 15 minutes daily. Your labor cost drops to $12.50 per shift, saving $13,542 annually. Factor in the elimination of forklift fuel, maintenance, and the reclaimed floor space previously dedicated to forklift aisles, and first-year savings approach $20,000. The $6,999 investment pays for itself before the warranty expires.

Machine utilization climbs correspondingly. Recovering 65 minutes per shift allows for two additional production cycles daily. If your average job generates $200 in revenue, that’s $400 more per shift, or $100,000 in annual top-line growth from a single material handling improvement.

Installation Without Disrupting Production

The countertop installation designation means the system bolts to your existing concrete floor rather than requiring a recessed pit. You’ll need a minimum 200mm thick concrete slab with 25MPa compressive strength—standard for industrial floors built after 1990. Installation involves drilling six anchor holes, leveling the base frame, and torquing bolts to 180 Nm. The pneumatic connection uses a standard 10mm push-to-connect fitting tying into your shop air at 6-7 bar pressure. Electrical requirements are modest: 380V three-phase, 15A circuit, which most shops can provision from existing machine panels.

Herochu provides a digital leveling tool with the system. Place it on the arm, and LEDs indicate which corner requires adjustment, eliminating guesswork and repeated measurements. The entire process, from uncrating to first production cycle, completes in one shift.

Certifications That Satisfy Your Customers’ Audits

The CE marking demonstrates compliance with Machinery Directive 2006/42/EC, covering mechanical integrity, control system safety, and electromagnetic immunity. If you supply Tier 1 automotive or medical device manufacturers, their supplier quality engineers recognize CE as a baseline requirement; it won’t automatically pass your audit, but it removes a major objection.

ISO 9001 certification of Herochu’s manufacturing facility ensures repeatability. The third-party audit verifies weld procedures, material traceability, and assembly work instructions. When your quality team inspects the delivered unit, dimensions match the approval drawings within ±2mm—consistency that matters when you’re aligning the manipulator with existing machine tooling.

Customization: Beyond Weight and Size

While the three standard variants cover most applications, customization addresses unique constraints. Need a longer arm reach to service two machines from a single pedestal? Herochu extends the horizontal beam to 4,500mm while upgrading the servo motor to maintain acceleration performance. Handling polished stainless that can’t tolerate suction cup marks? Specify cups with silicone sealing rings and reduced vacuum pressure.

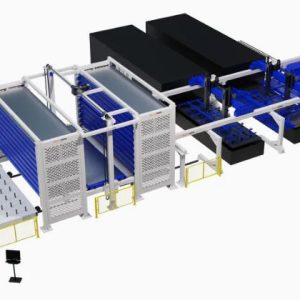

For shops running lights-out shifts, integrate a barcode reader on the arm. The operator scans the job traveler; the Omron control automatically selects the correct material from the rack and positions it per the programmed coordinates. This isn’t theoretical—it’s a deployed configuration in a high-end appliance manufacturer outside Stuttgart, where two manipulators feed three presses overnight without human intervention.

Maintenance: Built for Shop Floor Realities

The servo motors use absolute encoders, eliminating the need for homing routines after power cycles. If you do experience a fault, the Omron control’s built-in oscilloscope function captures motor current, position error, and I/O status during the incident. Email the trace file to Herochu support, and engineers diagnose root cause without traveling to your facility.

The oil-resistant suction cups last approximately 5,000 cycles before the sealing lip wears. Replacement takes five minutes using a supplied torque wrench—no special tools, no recalibration required. Keep two spare cups in your crib and change them during scheduled PM windows; you’ll never experience unplanned downtime from cup failure.

Final Word: The Right Tool for a Specific Problem

The Herochu Heavy Duty Steel Plate Manipulator doesn’t try to be a universal robot. It doesn’t weld, it doesn’t paint, and it doesn’t assemble. It simply moves heavy, flat sheets from a stack to a machine with speed, precision, and reliability. That focused design philosophy results in a system that costs one-third of a general-purpose industrial robot while delivering changeover times that are often faster because the kinematics are optimized for this single task.

Starting at $6,999, this isn’t a luxury capital purchase—it’s a productivity instrument that directly impacts your bottleneck. In a market where every fabricator competes on lead time and machine utilization, the question isn’t whether you can afford to automate material handling. It’s whether you can afford not to.

Factory

Hot Selling Machines

-

Heavy Duty Sheet Metal Storage Racks

Intelligent Production Line CNC Automated Storage Rack: Precision Meets Automation

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drawer-Style Sliding Sheet Metal Storage Rack – Efficient & Safe Material Handling

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Design for Steel Plate Storage with Heavy Duty Drawer Type Sheet Metal Rack Storage System

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Rack for Heavy Plates and Molds: Durable, Efficient Storage for Industrial Applications

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drive-In Pallet Rack Alternative: Space-Saving Drawer-Type Sheet Metal Storage with Automated Retrieval Compatibility

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Drawer Type Plate Shelves Warehouse Rack System for Industrial Metal Storage – 3-Ton Capacity per Layer

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Warehouse Storage System: Customizable Solutions for Metal Plate & Industrial Storage

Read moreRated 0 out of 5 -

Automated Storage Systems

Smart Fixed Profile Stereo Warehouse: Cost-Effective Automation for Small to Mid-Sized Fabrication Shops

Read moreRated 0 out of 5

Related products

Related products

-

Sheet Metal Handling Equipment

Gantry Loading System for Fiber Laser and Cutting Lines

Read moreRated 0 out of 5 -

Sheet Metal Handling Equipment

Laser Cutting with Gantry Loading and Unloading System of Smart Laser Automation

Read moreRated 0 out of 5 -

Sheet Metal Handling Equipment

High-Precision Servo Swing Arm Handling Manipulator

Read moreRated 0 out of 5