Fully Automatic Smart Industrial Long Material Warehouse

Storing long materials shouldn’t mean sacrificing speed, safety, or space. Yet most factories still rely on sprawling ground stacks or static racks that demand forklifts, multiple workers, and hours of searching. Herochu’s Fully Automatic Smart Industrial Long Material Warehouse dismantles these inefficiencies with a vertically integrated, sensor-driven platform built for the digital factory era.

Storing long materials shouldn’t mean sacrificing speed, safety, or space. Yet most factories still rely on sprawling ground stacks or static racks that demand forklifts, multiple workers, and hours of searching. Herochu’s Fully Automatic Smart Industrial Long Material Warehouse dismantles these inefficiencies with a vertically integrated, sensor-driven platform built for the digital factory era.

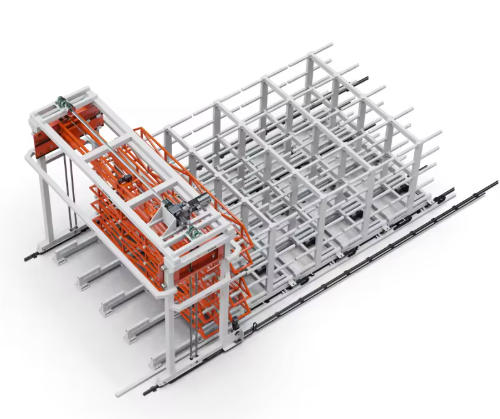

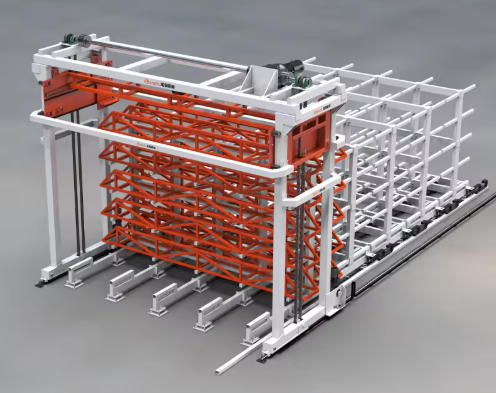

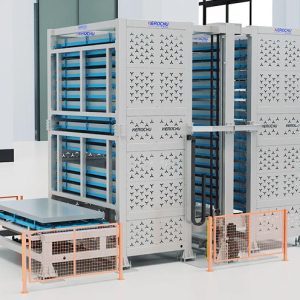

Developed by Hengzhu Machinery—a leader in industrial automation—the system merges mechanical robustness with intelligent logistics. Its core is a modular vertical tower available in 8–13 layers, each engineered to hold 3T or 5T of material ranging from 6015mm to 6025mm in length. Unlike horizontal cantilever racks that consume aisle after aisle, this unit rises upward, freeing floor space for production cells, assembly lines, or expansion.

What truly sets it apart is end-to-end automation. Using chain-driven linear rails, the retrieval mechanism moves with industrial-grade reliability at speeds up to 12 meters per minute during inbound/outbound cycles. A Siemens-based PLC control system orchestrates every action—from barcode scanning at intake to precise positioning at retrieval—with sub-millimeter accuracy. The result? A 3x improvement in operational throughput and near-zero misplacement rates.

The user interface is equally advanced. A 15-inch capacitive touchscreen offers intuitive workflows: select material ID, choose mode (manual/semi/full auto), and monitor real-time status. Maintenance alerts, usage logs, and energy consumption metrics are all accessible on-screen, enabling predictive servicing before failures occur.

Safety is embedded, not added. Emergency brakes engage instantly if vibration exceeds thresholds. Load cells verify weight before lifting. And the entire structure—fabricated from high-yield steel and finished with anti-corrosion coating—meets CE and ISO 9001 standards for global deployment.

Customization is seamless. Need taller layers for oversized I-beams? Done. Require integration with your SAP or Oracle WMS? Achievable. Even the profile support arms can be swapped—flat for sheets, contoured for pipes—without halting operations.

Priced from $35,999, this isn’t a cost—it’s a force multiplier. For metal service centers, shipyards, or renewable energy component manufacturers managing high-volume, long-item inventories, Herochu delivers a future-proof warehouse that thinks, moves, and scales with you.

Factory

Hot Selling Machines

-

Heavy Duty Sheet Metal Storage Racks

Intelligent Production Line CNC Automated Storage Rack: Precision Meets Automation

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drawer-Style Sliding Sheet Metal Storage Rack – Efficient & Safe Material Handling

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Design for Steel Plate Storage with Heavy Duty Drawer Type Sheet Metal Rack Storage System

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Rack for Heavy Plates and Molds: Durable, Efficient Storage for Industrial Applications

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drive-In Pallet Rack Alternative: Space-Saving Drawer-Type Sheet Metal Storage with Automated Retrieval Compatibility

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Drawer Type Plate Shelves Warehouse Rack System for Industrial Metal Storage – 3-Ton Capacity per Layer

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Warehouse Storage System: Customizable Solutions for Metal Plate & Industrial Storage

Read moreRated 0 out of 5 -

Automated Storage Systems

Smart Fixed Profile Stereo Warehouse: Cost-Effective Automation for Small to Mid-Sized Fabrication Shops

Read moreRated 0 out of 5

Related products

Related products

-

Automation Sheet Metal Material Warehouse

Automated Single-Tower Plate Warehousing Solution for Space-Constrained Workshops

Read moreRated 0 out of 5 -

Automation Sheet Metal Material Warehouse

Dual‑Tower Sheet Metal Storage Warehouse

Read moreRated 0 out of 5 -

Automation Sheet Metal Material Warehouse

Double-Tower Sheet Material Automated Storage and Retrieval System

Read moreRated 0 out of 5 -

Automation Sheet Metal Material Warehouse

Four-Bay Metal Sheet Storage Warehouse

Read moreRated 0 out of 5