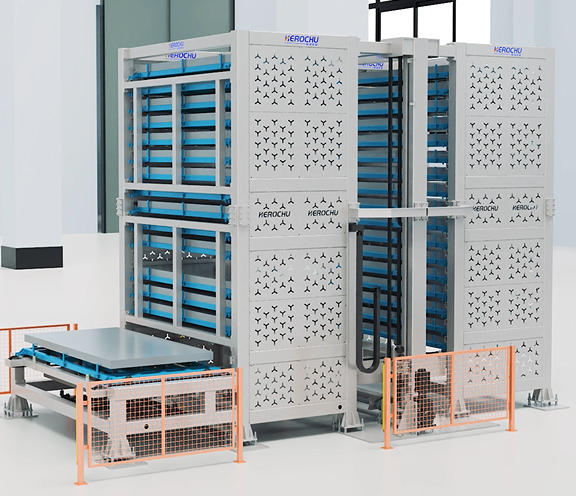

Double-Tower Sheet Material Automated Storage and Retrieval System

In today’s fast-paced manufacturing landscape, space efficiency, operational safety, and material integrity are non-negotiable. Traditional sheet metal storage methods—such as static cantilever racks or open floor stacking—are increasingly inadequate for modern production demands. Enter the Double-Tower Sheet Material Automated Storage and Retrieval System, a cutting-edge solution engineered to maximize vertical space, eliminate manual handling risks, and dramatically improve workflow throughput.

Revolutionizing Industrial Storage with the Double-Tower Sheet Material Automated Storage and Retrieval System

In today’s fast-paced manufacturing landscape, space efficiency, operational safety, and material integrity are non-negotiable. Traditional sheet metal storage methods—such as static cantilever racks or open floor stacking—are increasingly inadequate for modern production demands. Enter the Double-Tower Sheet Material Automated Storage and Retrieval System, a cutting-edge solution engineered to maximize vertical space, eliminate manual handling risks, and dramatically improve workflow throughput.

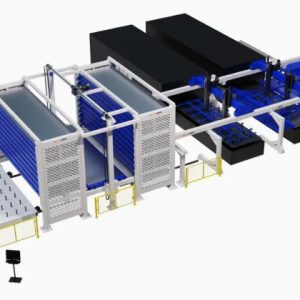

This advanced system leverages a dual-tower architecture to deliver unparalleled storage density. Occupying just 280 square feet of floor space, it can store up to 448,800 pounds (over 224 tons) of sheet metal—an astonishing feat that translates into up to 80% floor space savings compared to conventional racking. For manufacturers operating in high-cost industrial zones or constrained facilities, this level of spatial optimization isn’t just convenient—it’s transformative.

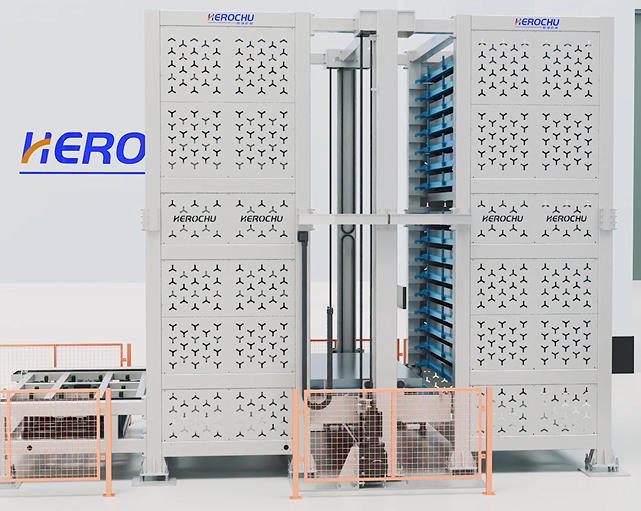

At the core of the system is a centralized, motorized lift mechanism positioned between two vertical storage towers. Each tower features 8 to 13 floors, depending on facility ceiling height and operational needs, with each storage level rated for either 3 or 5 metric tons. The modular design supports standard and oversized sheet formats—including 4′ x 8′, 5′ x 10′, 6′ x 12′, and 2m x 4m plates—making it adaptable across industries from automotive fabrication to aerospace component manufacturing.

What truly sets the Double-Tower Sheet Material Automated Storage and Retrieval System apart is its intelligent engineering. By relocating drive motors to the side towers and optimizing the lift carriage geometry, mechanical stress is significantly reduced. This not only enhances system longevity but also enables a vertical lifting speed of 9 meters per minute and an inlet/outlet speed of 12 meters per minute. Operators can retrieve any stored sheet with a single button press, eliminating time-consuming forklift maneuvers and reducing retrieval cycles by over 60%.

Safety is another cornerstone of this system. Heavy sheet metal handling has long posed ergonomic and injury risks—pinch points, dropped loads, and repetitive strain injuries are common in manual environments. The automated double-tower system fully encloses materials during storage and delivers them directly to an ergonomic ground-level access point. No overhead cranes, no forklift traffic, no manual lifting. This not only protects workers but also reduces reliance on certified forklift operators, lowering labor costs and compliance burdens.

Moreover, the system minimizes material damage. In traditional setups, sheets are frequently scratched, dented, or warped due to improper stacking or rough handling. Here, each plate is stored in a dedicated cartridge or support frame (with optional plate support configurations), ensuring minimal contact and consistent alignment. For industries where surface finish is critical—such as defense, medical device manufacturing, or premium architectural metalwork—this precision handling preserves material value and reduces scrap rates.

Integration into existing workflows is seamless. The system communicates with enterprise resource planning (ERP) and manufacturing execution systems (MES) via standard industrial protocols, enabling real-time inventory tracking and just-in-time material delivery. Whether feeding a laser cutter, press brake, or CNC shear, the Double-Tower system ensures the right material arrives at the right station, precisely when needed.

For companies evaluating warehouse automation, ROI is often a key concern. With this system, payback periods are typically under three years—driven by space savings, reduced labor costs, lower insurance premiums (due to improved safety), and decreased material waste. And unlike sprawling horizontal expansions, this vertical solution requires no new construction, making it ideal for urban facilities or leased spaces with footprint restrictions.

In summary, the Double-Tower Sheet Material Automated Storage and Retrieval System represents a paradigm shift in industrial material handling. It’s not merely a storage rack—it’s an integrated logistics node that enhances productivity, safeguards personnel, and future-proofs operations against rising space and labor costs. As manufacturers worldwide seek smarter, leaner, and safer ways to manage raw materials, this dual-tower innovation stands out as a benchmark in automated warehouse racking solutions.

Factory

Hot Selling Machines

-

Heavy Duty Sheet Metal Storage Racks

Intelligent Production Line CNC Automated Storage Rack: Precision Meets Automation

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drawer-Style Sliding Sheet Metal Storage Rack – Efficient & Safe Material Handling

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Design for Steel Plate Storage with Heavy Duty Drawer Type Sheet Metal Rack Storage System

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Rack for Heavy Plates and Molds: Durable, Efficient Storage for Industrial Applications

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drive-In Pallet Rack Alternative: Space-Saving Drawer-Type Sheet Metal Storage with Automated Retrieval Compatibility

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Drawer Type Plate Shelves Warehouse Rack System for Industrial Metal Storage – 3-Ton Capacity per Layer

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Warehouse Storage System: Customizable Solutions for Metal Plate & Industrial Storage

Read moreRated 0 out of 5 -

Automated Storage Systems

Smart Fixed Profile Stereo Warehouse: Cost-Effective Automation for Small to Mid-Sized Fabrication Shops

Read moreRated 0 out of 5

Related products

Related products

-

Automation Sheet Metal Material Warehouse

Automatic Sheet Metal Storage & Retrieval System (AS/RS) – Automated Loading Unloading Racks

Read moreRated 0 out of 5 -

Automation Sheet Metal Material Warehouse

Maximizing Efficiency with Dual-Tower Automated Storage Solutions

Read moreRated 0 out of 5 -

Automation Sheet Metal Material Warehouse

Fully Automatic Vertical Profile Smart Storage Unit

Read moreRated 0 out of 5 -

Automation Sheet Metal Material Warehouse

Four-Bay Metal Sheet Storage Warehouse

Read moreRated 0 out of 5