Laser Cutting Loading Machine

In today’s fast-paced metal fabrication industry, efficiency, accuracy, and consistency are non-negotiable. One of the most transformative innovations enhancing these core values is the Laser Cutting Loading Machine—an automated auxiliary system designed to streamline material handling before the cutting process begins. Far from being a mere conveyor, this intelligent machine integrates seamlessly with laser cutting tables to deliver raw or pre-cut sheets with pinpoint precision, reducing human intervention and maximizing throughput.

In today’s fast-paced metal fabrication industry, efficiency, accuracy, and consistency are non-negotiable. One of the most transformative innovations enhancing these core values is the Laser Cutting Loading Machine—an automated auxiliary system designed to streamline material handling before the cutting process begins. Far from being a mere conveyor, this intelligent machine integrates seamlessly with laser cutting tables to deliver raw or pre-cut sheets with pinpoint precision, reducing human intervention and maximizing throughput.

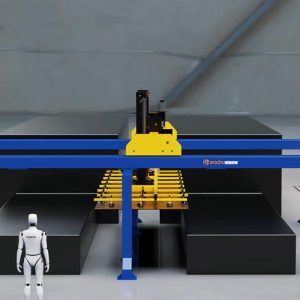

At its core, the laser cutting loading machine functions as the “first responder” in the production line. It automatically transports sheet metal—ranging from thin-gauge stainless steel to thick carbon steel plates—from storage racks or pallets directly onto the laser cutting bed. This eliminates manual lifting, minimizes positioning errors, and significantly cuts cycle time between jobs. Whether your shop runs high-volume production or complex one-off parts, this automation ensures consistent material placement, which is critical for achieving tight tolerances and clean edge finishes.

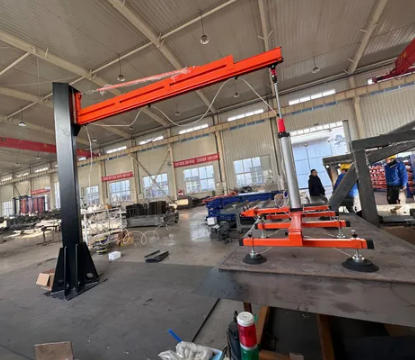

The machine typically employs one or more of three gripping technologies: mechanical clamps, pneumatic actuators, or vacuum suction systems. Among these, vacuum adsorption is the most widely adopted due to its gentleness on surface finishes and adaptability to various sheet sizes and materials—including aluminum, galvanized steel, and coated metals. Advanced models feature arrays of independently controlled suction cups that adjust dynamically to warped or uneven sheets, maintaining secure grip without marring the surface.

What truly sets modern laser cutting loading machines apart is their intelligence. Integrated with CNC control systems or factory MES software, they can automatically recognize material dimensions, thickness, and even orientation using vision sensors or barcode/RFID scanning. Once identified, the machine calculates the optimal pickup point, travel path, and drop-off coordinates on the cutting table. This level of automation not only prevents collisions but also enables unattended operation during off-hours—boosting overall equipment effectiveness (OEE).

Safety and compliance are equally prioritized. Units designed for European or North American markets often carry CE certification, featuring emergency stop circuits, light curtains, and anti-collision sensors. Operators interact with the system via intuitive HMI panels, where job parameters can be loaded with a single tap—no programming expertise required.

Moreover, the laser cutting loading machine supports lean manufacturing principles. By reducing reliance on manual labor for repetitive tasks, it lowers ergonomic injury risks and frees skilled workers for higher-value activities like quality inspection or machine maintenance. Over time, shops report 20–40% increases in daily output and significant reductions in material waste due to misalignment or double-loading errors.

Available in standard configurations for common sheet formats (up to 4000×1500 mm) and customizable builds for oversized or specialty materials, this equipment scales with business growth. Whether integrated into a new laser cell or retrofitted to an existing setup, the laser cutting loading machine is not just a tool—it’s a strategic investment in productivity, precision, and workplace safety.

Factory

Hot Selling Machines

-

Heavy Duty Sheet Metal Storage Racks

Intelligent Production Line CNC Automated Storage Rack: Precision Meets Automation

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drawer-Style Sliding Sheet Metal Storage Rack – Efficient & Safe Material Handling

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Design for Steel Plate Storage with Heavy Duty Drawer Type Sheet Metal Rack Storage System

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Rack for Heavy Plates and Molds: Durable, Efficient Storage for Industrial Applications

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drive-In Pallet Rack Alternative: Space-Saving Drawer-Type Sheet Metal Storage with Automated Retrieval Compatibility

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Drawer Type Plate Shelves Warehouse Rack System for Industrial Metal Storage – 3-Ton Capacity per Layer

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Warehouse Storage System: Customizable Solutions for Metal Plate & Industrial Storage

Read moreRated 0 out of 5 -

Automated Storage Systems

Smart Fixed Profile Stereo Warehouse: Cost-Effective Automation for Small to Mid-Sized Fabrication Shops

Read moreRated 0 out of 5

Related products

Related products

-

Sheet Metal Handling Equipment

Innovative Material Handling Solutions: The Servo Swing Arm Manipulator for CNC Operations

Read moreRated 0 out of 5 -

Sheet Metal Handling Equipment

Automatic Loading and Unloading System for Fiber Laser Cutting Machine

Read moreRated 0 out of 5 -

Sheet Metal Handling Equipment

Automatic Storage System Steel Metal Plate Gantry Loading Unloading Robot Manipulator

Read moreRated 0 out of 5 -

Sheet Metal Handling Equipment

Steel Plate Material Handling Equipment for Modern Manufacturing

Read moreRated 0 out of 5