Advanced Telescopic Cantilever Storage Solutions of Industrial Storage

The evolution of warehouse technology has brought us far beyond simple pallet racking. Today, Telescopic Cantilever Storage systems represent the pinnacle of intelligent design for long, bulky, or irregular cargo. From aluminum extrusions to wooden beams, from PVC conduits to steel I-beams, these racks provide a universal answer to one of logistics’ oldest problems: how to store elongated materials safely, accessibly, and space-efficiently.

Revolutionize Industrial Storage with Advanced Telescopic Cantilever Storage Solutions

The evolution of warehouse technology has brought us far beyond simple pallet racking. Today, Telescopic Cantilever Storage systems represent the pinnacle of intelligent design for long, bulky, or irregular cargo. From aluminum extrusions to wooden beams, from PVC conduits to steel I-beams, these racks provide a universal answer to one of logistics’ oldest problems: how to store elongated materials safely, accessibly, and space-efficiently.

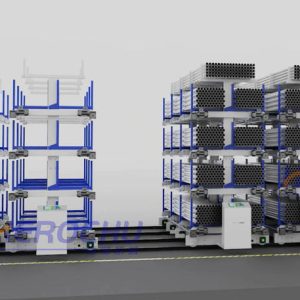

At the heart of this system is its modular, user-configurable architecture. Every dimension—arm length, layer height, number of tiers, and overall rack depth—can be customized to match specific inventory profiles. Need to store 9-meter composite rods alongside 4-meter copper tubes? No problem. The telescopic arms adjust independently, ensuring each item rests securely without overhang or instability.

Durability is non-negotiable in industrial settings, which is why these racks are fabricated from high-tensile steel and finished with electrostatic powder coating for resistance against impact, chemicals, and humidity. Optional galvanization is available for outdoor or high-moisture environments.

Operationally, telescopic cantilever storage shines in its synergy with material handling equipment. Overhead bridge cranes can lift and place items directly onto extended arms, eliminating manual lifting and minimizing product handling. In automated versions, PLC-controlled electric drives allow remote or scheduled extension/retraction—ideal for integration into smart warehouses using WMS or IoT tracking.

Space savings are dramatic. By stacking vertically and eliminating the need for wide access lanes (since arms bring goods to the operator), facilities can increase storage density by up to 60%. This is especially valuable in urban warehouses where real estate costs are prohibitive.

Furthermore, the system supports FIFO (First-In, First-Out) or LIFO strategies through strategic labeling and zoning. Leftover offcuts can be stored on dedicated trays within the same bay, reducing waste and simplifying reuse.

Whether you’re a small machine shop upgrading from floor piles or a multinational distributor managing thousands of SKUs, Telescopic Cantilever Storage offers scalable, future-proof infrastructure. With global supply chains demanding faster turnaround and tighter inventory control, this technology isn’t just convenient—it’s indispensable.

Choose innovation. Choose efficiency. Choose telescopic cantilever storage—where every inch of space works as hard as your team does.

Factory

Hot Selling Machines

-

Heavy Duty Sheet Metal Storage Racks

Intelligent Production Line CNC Automated Storage Rack: Precision Meets Automation

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drawer-Style Sliding Sheet Metal Storage Rack – Efficient & Safe Material Handling

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Design for Steel Plate Storage with Heavy Duty Drawer Type Sheet Metal Rack Storage System

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Rack for Heavy Plates and Molds: Durable, Efficient Storage for Industrial Applications

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drive-In Pallet Rack Alternative: Space-Saving Drawer-Type Sheet Metal Storage with Automated Retrieval Compatibility

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Drawer Type Plate Shelves Warehouse Rack System for Industrial Metal Storage – 3-Ton Capacity per Layer

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Warehouse Storage System: Customizable Solutions for Metal Plate & Industrial Storage

Read moreRated 0 out of 5 -

Automated Storage Systems

Smart Fixed Profile Stereo Warehouse: Cost-Effective Automation for Small to Mid-Sized Fabrication Shops

Read moreRated 0 out of 5

Related products

Related products

-

Heavy Duty Cantilever Racking System

Double-Sided Cantilever Rack: Maximize Storage Space with Heavy-Duty Efficiency

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Rail Type Telescopic Cantilever Shelves for Profile Steel Pipe Storage

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Drive-In Foldable Vertical Storage System – Space-Saving Innovation for Narrow Aisles

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Maximize Storage Efficiency with a Heavy Duty 5+1Layer Steel Cantilever Rack

Read moreRated 0 out of 5