Laser Cutting with Gantry Loading and Unloading System of Smart Laser Automation

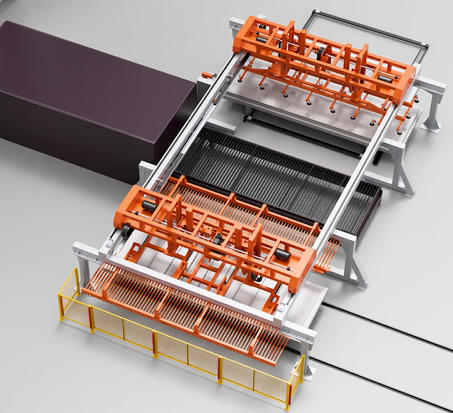

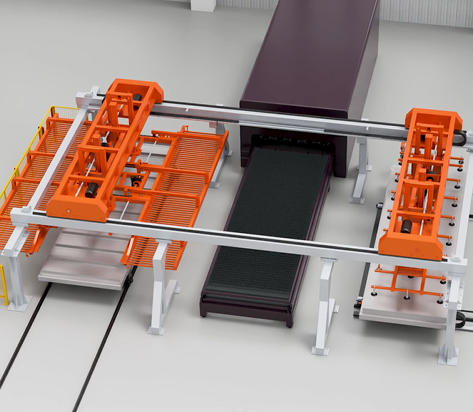

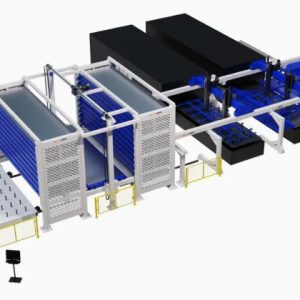

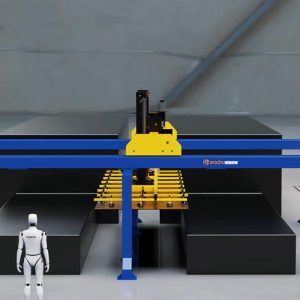

The Gantry Loading and Unloading Pneumatic Manipulator Industry Robot represents a groundbreaking advancement in industrial automation, particularly for laser cutting applications. This innovative system utilizes a gantry structure spanning above the working area of laser cutting machines, equipped with linear guide rails on the X and Y axes for precise material transportation. The system’s design allows for movement and carrying devices to transport materials with exceptional accuracy and efficiency.

Introduction to Gantry Loading and Unloading Systems

The Gantry Loading and Unloading Pneumatic Manipulator Industry Robot represents a groundbreaking advancement in industrial automation, particularly for laser cutting applications. This innovative system utilizes a gantry structure spanning above the working area of laser cutting machines, equipped with linear guide rails on the X and Y axes for precise material transportation. The system’s design allows for movement and carrying devices to transport materials with exceptional accuracy and efficiency.

Core Advantages of Gantry Systems

-

Enhanced Stability and Load Capacity: The robust gantry structure provides unparalleled stability, enabling the handling of large-sized or heavy-duty sheet metal components. This makes it particularly suitable for industries requiring the processing of substantial metal sheets, such as shipbuilding and heavy machinery manufacturing.

-

Increased Coverage Area: The gantry design offers a large coverage area, allowing for more extensive material handling within the same footprint compared to traditional robotic systems.

-

High-Speed Operation: With optimized pneumatic manipulation, these systems can achieve rapid material transfer, significantly reducing cycle times in production environments.

-

Precision Positioning: The combination of linear guide rails and advanced control systems ensures micron-level accuracy in material placement, crucial for high-precision laser cutting applications.

Factory

Hot Selling Machines

-

Heavy Duty Sheet Metal Storage Racks

Intelligent Production Line CNC Automated Storage Rack: Precision Meets Automation

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drawer-Style Sliding Sheet Metal Storage Rack – Efficient & Safe Material Handling

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Design for Steel Plate Storage with Heavy Duty Drawer Type Sheet Metal Rack Storage System

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Rack for Heavy Plates and Molds: Durable, Efficient Storage for Industrial Applications

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drive-In Pallet Rack Alternative: Space-Saving Drawer-Type Sheet Metal Storage with Automated Retrieval Compatibility

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Drawer Type Plate Shelves Warehouse Rack System for Industrial Metal Storage – 3-Ton Capacity per Layer

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Warehouse Storage System: Customizable Solutions for Metal Plate & Industrial Storage

Read moreRated 0 out of 5 -

Automated Storage Systems

Smart Fixed Profile Stereo Warehouse: Cost-Effective Automation for Small to Mid-Sized Fabrication Shops

Read moreRated 0 out of 5

Related products

Related products

-

Sheet Metal Handling Equipment

Gantry Robot Auto Load System for Laser Cutter

Read moreRated 0 out of 5 -

Sheet Metal Handling Equipment

High-Precision Servo Swing Arm Handling Manipulator

Read moreRated 0 out of 5 -

Sheet Metal Handling Equipment

Automatic Storage System Steel Metal Plate Gantry Loading Unloading Robot Manipulator

Read moreRated 0 out of 5