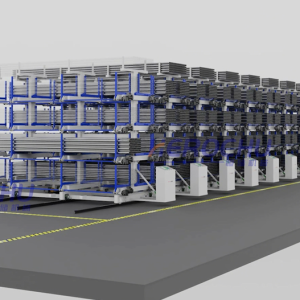

Adjustable Length Steel Cantilever Rack – Flexible, Scalable Storage for Dynamic Warehouses

Warehouse needs evolve. Product lines expand, material lengths vary, and space constraints shift. Rigid storage systems quickly become obsolete. Enter the Adjustable Length Steel Cantilever Rack—a dynamic, future-ready solution that grows with your business.This innovative system features telescopic or modular arm assemblies that allow on-site adjustment of storage length from 3,000mm up to 12,000mm+, eliminating the need for multiple rack types. Whether you’re switching from 4-meter PVC conduits to 10-meter galvanized steel pipes, the same rack adapts within hours—not weeks.

Warehouse needs evolve. Product lines expand, material lengths vary, and space constraints shift. Rigid storage systems quickly become obsolete. Enter the Adjustable Length Steel Cantilever Rack—a dynamic, future-ready solution that grows with your business.

This innovative system features telescopic or modular arm assemblies that allow on-site adjustment of storage length from 3,000mm up to 12,000mm+, eliminating the need for multiple rack types. Whether you’re switching from 4-meter PVC conduits to 10-meter galvanized steel pipes, the same rack adapts within hours—not weeks.

The core structure uses high-tensile steel columns with pre-punched holes at standardized intervals, enabling vertical repositioning of arms to match load height requirements. Arm lengths are also customizable (550mm to 800mm+), ensuring optimal support for narrow bundles or wide flange beams. This adjustability maximizes cube utilization—critical in high-rent urban warehouses or vertically constrained facilities.

Load capacity remains uncompromised despite flexibility. Each layer supports up to 6 tons, with total rack capacities scalable through column reinforcement and baseplate anchoring. The HC-G6053S model, for instance, delivers 2 tons per layer over 6 meters in a compact 1,750mm height—perfect for SMEs with limited ceiling clearance.

Operationally, the system supports both manual and powered mobility. Electric-assist drive units (with PLC frequency control) enable effortless repositioning of entire rack sections, ideal for high-throughput distribution centers. For budget-conscious operations, a rugged hand-crank mechanism provides reliable manual movement with minimal effort.

Durability is assured through industrial-grade powder coating in high-visibility colors (orange/blue), enhancing safety while resisting chipping, UV degradation, and chemical exposure. The double-layer arm design includes integrated stops to prevent material roll-off—a crucial feature for round stock like rebar or copper tubing.

From automotive suppliers storing drive shafts to aerospace fabricators managing composite spars, this rack serves diverse sectors. Its true value lies in agility: no more costly retrofits or underutilized racks when product specs change. Simply reconfigure, reload, and resume operations.

In an era where supply chains demand responsiveness, the Adjustable Length Steel Cantilever Rack transforms static storage into a strategic, adaptive resource.

Factory

Hot Selling Machines

-

Heavy Duty Sheet Metal Storage Racks

Intelligent Production Line CNC Automated Storage Rack: Precision Meets Automation

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drawer-Style Sliding Sheet Metal Storage Rack – Efficient & Safe Material Handling

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Design for Steel Plate Storage with Heavy Duty Drawer Type Sheet Metal Rack Storage System

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Rack for Heavy Plates and Molds: Durable, Efficient Storage for Industrial Applications

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drive-In Pallet Rack Alternative: Space-Saving Drawer-Type Sheet Metal Storage with Automated Retrieval Compatibility

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Drawer Type Plate Shelves Warehouse Rack System for Industrial Metal Storage – 3-Ton Capacity per Layer

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Warehouse Storage System: Customizable Solutions for Metal Plate & Industrial Storage

Read moreRated 0 out of 5 -

Automated Storage Systems

Smart Fixed Profile Stereo Warehouse: Cost-Effective Automation for Small to Mid-Sized Fabrication Shops

Read moreRated 0 out of 5

Related products

Related products

-

Heavy Duty Cantilever Racking System

Roll-Out Telescopic Cantilever Rack for Streamlined Operations

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Rail-type telescopic cantilever shelves

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Drive-In Foldable Vertical Storage System – Space-Saving Innovation for Narrow Aisles

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

High-Capacity Long Material Storage Cantilever Rack – Engineered for Industrial Precision

Read moreRated 0 out of 5