Automated Telescopic Cantilever Rack with Telescopic Arms

In today’s fast-paced industrial environment, automation has become a key driver of efficiency and productivity. When it comes to storing and retrieving tubes and other long materials, traditional storage solutions often fall short, requiring excessive manual labor and leading to inefficiencies. The Automated Telescopic Cantilever Rack with Telescopic Arms is here to change that, revolutionizing tube storage with its advanced automation features, exceptional capacity, and user-friendly design.

In today’s fast-paced industrial environment, automation has become a key driver of efficiency and productivity. When it comes to storing and retrieving tubes and other long materials, traditional storage solutions often fall short, requiring excessive manual labor and leading to inefficiencies. The Automated Telescopic Cantilever Rack with Telescopic Arms is here to change that, revolutionizing tube storage with its advanced automation features, exceptional capacity, and user-friendly design.

At the core of this automated rack system is its telescopic arms, which are equipped with high-precision ball bearing guide rails. These guide rails ensure that the arms slide smoothly and effortlessly, even when carrying heavy loads. The automated operation of the telescopic arms eliminates the need for manual pushing or pulling, reducing labor costs and minimizing the risk of worker fatigue and injury. With just the touch of a button, the arms can extend outside the cargo position, allowing for easy loading and unloading of tubes using cranes or other material handling equipment.

Safety is a top priority in any industrial setting, and this automated rack system is designed with multiple safety features to protect both workers and materials. The sliding-type guide rail is paired with a foot rolling protection device, which effectively prevents the telescopic arms from accidentally sliding down or overturning. This is particularly important when the arms are extended and carrying heavy tubes, as it eliminates the risk of dangerous accidents. Additionally, the precise welding techniques and thickened columns ensure that the rack system remains stable even under maximum load, further enhancing safety.

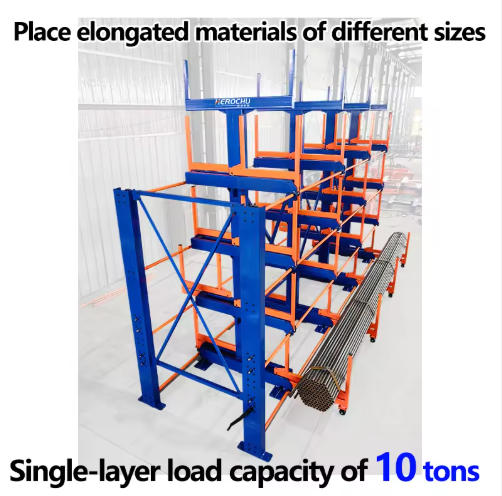

Constructed from high-strength carbon steel, the Automated Telescopic Cantilever Rack is built to last. The carbon steel material provides exceptional strength and durability, allowing the rack to handle up to 100,000kg with ease. Each layer can support up to 5 tons per side, making it suitable for storing a wide range of tube sizes and weights—from small-diameter tubes to large, heavy-duty industrial tubes. The surface of the rack is powder-coated, which not only gives it a sleek, professional appearance but also provides excellent resistance to corrosion, rust, and wear. This powder coating ensures that the rack can withstand the harsh conditions of industrial warehouses, including exposure to moisture, dust, and chemicals.

Versatility is another key feature of this automated rack system. It is available in multiple layer configurations (3-layer, 4-layer, and 5-layer) and layer lengths (6m, 9m, and 12m), allowing you to customize the rack to fit your specific storage needs and warehouse dimensions. The color of the rack can also be customized to match your warehouse’s decor or branding. For facilities that handle both tubes and sheets, optional sheet support devices are available, enabling the storage and retrieval of sheets of different sizes with gentle precision.

The transmission system of the Automated Telescopic Cantilever Rack is engineered for reliability and efficiency. The drive end uses a sprocket chain transmission to transfer power to the movable arms through transmission rods, which is then converted into a gear rack transmission. This combination of sprocket chain and gear rack transmission ensures smooth, precise movement of the telescopic arms, even under heavy loads. The vertical storage and retrieval operation made possible by this transmission system allows for efficient use of vertical space, maximizing storage density and optimizing warehouse layout.

This automated rack system is manufactured by Jinan Constant Storage Machinery Manufacturing Co. LTD, a leading provider of warehousing equipment with a comprehensive range of services. Jinan Constant integrates research and development, production, sales, installation, and service, ensuring that every aspect of the rack system meets the highest quality standards. The company specializes in a variety of storage solutions, including laser cutting sheet metal storage shelves, drawer-type sheet metal storage shelves, and automatic loading and unloading sheet metal material warehouses—making them well-equipped to handle the unique needs of tube storage.

One of the key advantages of working with Jinan Constant is their ability to provide customized solutions. They understand that every warehouse and application is unique, and they work closely with clients to design a rack system that meets their specific storage requirements. Whether you need a rack system for a small workshop or a large-scale industrial facility, Jinan Constant can tailor the design to fit your needs. Additionally, their self-operated factory enables fast delivery, with one-stop service from design and manufacturing to installation—ensuring that your rack system is up and running as quickly as possible.

The Automated Telescopic Cantilever Rack with Telescopic Arms is ideal for use in the machinery manufacturing industry, pipe and profile manufacturing industry, and any other industry that requires efficient storage of long materials. By combining automation, safety, durability, and versatility, this rack system revolutionizes tube storage, helping businesses improve efficiency, reduce costs, and enhance workplace safety. If you’re looking for a state-of-the-art storage solution for your tubes, this automated telescopic cantilever rack is the perfect choice.

Factory

Hot Selling Machines

-

Heavy Duty Sheet Metal Storage Racks

Intelligent Production Line CNC Automated Storage Rack: Precision Meets Automation

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drawer-Style Sliding Sheet Metal Storage Rack – Efficient & Safe Material Handling

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Design for Steel Plate Storage with Heavy Duty Drawer Type Sheet Metal Rack Storage System

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Rack for Heavy Plates and Molds: Durable, Efficient Storage for Industrial Applications

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drive-In Pallet Rack Alternative: Space-Saving Drawer-Type Sheet Metal Storage with Automated Retrieval Compatibility

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Drawer Type Plate Shelves Warehouse Rack System for Industrial Metal Storage – 3-Ton Capacity per Layer

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Warehouse Storage System: Customizable Solutions for Metal Plate & Industrial Storage

Read moreRated 0 out of 5 -

Automated Storage Systems

Smart Fixed Profile Stereo Warehouse: Cost-Effective Automation for Small to Mid-Sized Fabrication Shops

Read moreRated 0 out of 5

Related products

Related products

-

Heavy Duty Cantilever Racking System

Roll Out Telescopic Cantilever Pipe Rack Systems

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Innovative Pipe Storage Rack & Steel Cantilever Storage Rack System: Organize Long Materials Efficiently

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Roll Out Cantilever Racking & Telesscopic Cantilever Pipe Rack

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Electric Heavy Duty Steel Pipe Cantilever Rack – Automated Efficiency for High-Volume Operations

Read moreRated 0 out of 5