Heavy Duty Roll Out Sheet Metal Storage Rack: The Ultimate Solution for Fabrication Shop Efficiency

In the fast-paced environment of a fabrication shop, every square foot of space and every minute of workflow counts. Disorganized sheet metal, steel plates, and other heavy materials not only waste valuable floor space but also pose significant safety risks and slow down production processes. This is where the Heavy Duty Roll Out Sheet Metal Storage Rack comes into play—engineered to transform how fabrication shops store, access, and manage their critical materials. Designed with flexibility, durability, and efficiency at its core, this storage solution is more than just a rack; it’s a strategic investment that enhances safety, boosts productivity, and drives profitability for your business.

In the fast-paced environment of a fabrication shop, every square foot of space and every minute of workflow counts. Disorganized sheet metal, steel plates, and other heavy materials not only waste valuable floor space but also pose significant safety risks and slow down production processes. This is where the Heavy Duty Roll Out Sheet Metal Storage Rack comes into play—engineered to transform how fabrication shops store, access, and manage their critical materials. Designed with flexibility, durability, and efficiency at its core, this storage solution is more than just a rack; it’s a strategic investment that enhances safety, boosts productivity, and drives profitability for your business.

Fabrication shop sheet metal storage rack systems are often tasked with handling large, heavy, and unwieldy materials that are essential to daily operations. Traditional storage methods, such as stacking materials on the floor or using basic shelving, frequently lead to cluttered workspaces, increased risk of material damage, and time-consuming searches for the right sheet or plate. The Heavy Duty Roll Out Sheet Metal Storage Rack eliminates these pain points by elevating materials off the floor and providing a dynamic, accessible storage system that puts every item within easy reach of your team.

One of the standout features of this roll out rack is its modular and flexible design. Fabrication shops rarely have static needs—project scopes change, material types vary, and production volumes fluctuate. Our roll out sheet metal racks adapt seamlessly to these changes, allowing you to reconfigure or alter the system as your requirements evolve. This flexibility means you won’t have to invest in new storage solutions every time your operations shift, providing long-term value and adaptability.

When it comes to storage capacity, the Heavy Duty Roll Out Sheet Metal Storage Rack is second to none. Our standard design can accommodate up to 12 drawers, creating an organized, dense storage system that maximizes vertical space and minimizes floor footprint. This dense storage capability is particularly beneficial for fabrication shops where space is at a premium, allowing you to store more materials without expanding your facility. Each level of the rack boasts an impressive load capacity of 5,000 lbs, making it ideal for heavy steel plates, alloy steel sheets, aluminum panels, and other weighty materials commonly used in fabrication processes.

Durability is non-negotiable in a fabrication shop setting, and our roll out sheet metal racks are built to withstand the rigors of industrial use. 100% Canadian made, these racks are constructed with high-quality materials and rigorous manufacturing standards, ensuring unmatched build quality and longevity. The corrosion-protected, powder-coated steel construction enhances resistance against rust and wear, even in the harsh environments often found in fabrication shops—where dust, moisture, and chemical exposure are common. This durability translates to a longer lifespan for your storage system, reducing maintenance costs and replacement frequency over time.

Ergonomics and safety are central to the design of our Heavy Duty Roll Out Sheet Metal Storage Rack. The roll out mechanism is engineered to deliver materials directly to the picker, eliminating the need for excessive bending, reaching, or lifting—actions that contribute to workplace injuries. By keeping materials organized and accessible, the rack also reduces the risk of tripping hazards and material collisions, creating a safer work environment for your team. Additionally, the skeletal structural design provides robust stability, ensuring that even heavy loads are securely supported, further minimizing safety risks.

At Jinan Hengchu Storage Machinery Manufacturing Co., Ltd., we understand that every fabrication shop has unique needs. That’s why our Heavy Duty Roll Out Sheet Metal Storage Racks are completely customizable. You can choose from a variety of configurations, including layer lengths ranging from 2.5m to 6m, to suit the specific dimensions of your materials and your warehouse space. Our team offers exclusive one-on-one service, providing free design drawings tailored to your requirements and on-site installation to ensure your storage system is set up correctly and efficiently.

As a direct manufacturer with over 15 years of industry experience, we take pride in delivering high-quality storage solutions that meet the demands of fabrication shops. We welcome orders of any size, from a single unit to large-scale installations, and our professional after-sales team is on hand to address any questions or concerns you may have. Whether you’re storing materials for laser cutting, shearing, or other fabrication processes, our Heavy Duty Roll Out Sheet Metal Storage Rack is designed to integrate seamlessly with your operations, enhancing efficiency and streamlining your workflow.

Investing in the right storage system is crucial for the success of any fabrication shop. The Heavy Duty Roll Out Sheet Metal Storage Rack offers the perfect combination of flexibility, durability, capacity, and safety—all designed to help you make the most of your space and resources. Contact us today to share your storage requirements, and let our team develop a personalized solution that drives productivity and profitability for your business.

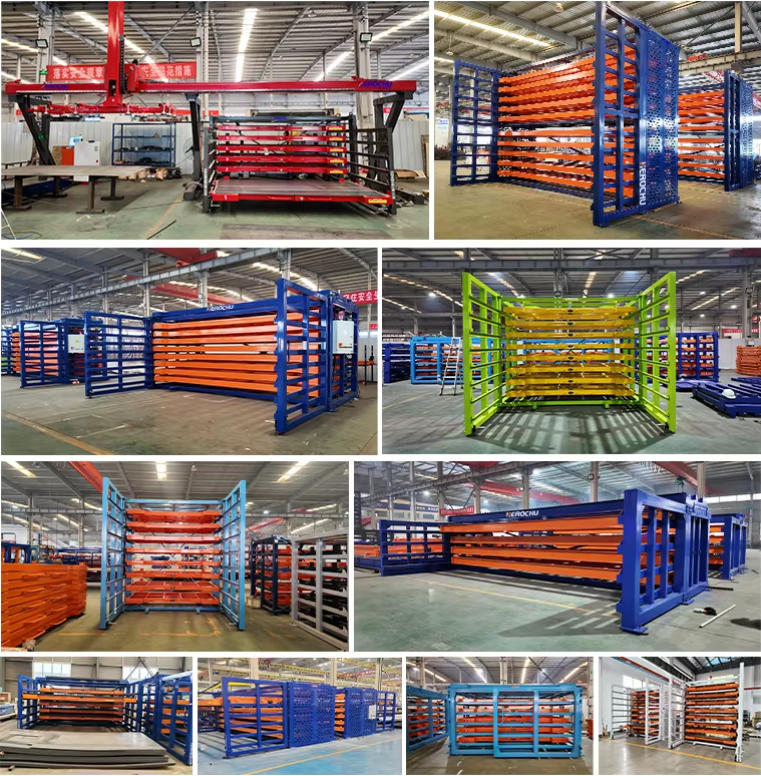

Factory

Hot Selling Machines

-

Heavy Duty Sheet Metal Storage Racks

Intelligent Production Line CNC Automated Storage Rack: Precision Meets Automation

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drawer-Style Sliding Sheet Metal Storage Rack – Efficient & Safe Material Handling

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Design for Steel Plate Storage with Heavy Duty Drawer Type Sheet Metal Rack Storage System

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Rack for Heavy Plates and Molds: Durable, Efficient Storage for Industrial Applications

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drive-In Pallet Rack Alternative: Space-Saving Drawer-Type Sheet Metal Storage with Automated Retrieval Compatibility

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Drawer Type Plate Shelves Warehouse Rack System for Industrial Metal Storage – 3-Ton Capacity per Layer

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Warehouse Storage System: Customizable Solutions for Metal Plate & Industrial Storage

Read moreRated 0 out of 5 -

Automated Storage Systems

Smart Fixed Profile Stereo Warehouse: Cost-Effective Automation for Small to Mid-Sized Fabrication Shops

Read moreRated 0 out of 5

Related products

Related products

-

Heavy Duty Sheet Metal Storage Racks

Custom Storage Rack for 6-Meter Plates and Heavy Loads

Read moreRated 0 out of 5