Heavy Duty Pipe Storage Rack: Crank-Out Cantilever Design for Industrial Strength and Accessibility

When it comes to storing heavy, long materials like steel pipes, bars, and tubes, a one-size-fits-all storage solution simply won’t cut it. Industrial facilities require a storage system that offers exceptional strength, easy accessibility, and space efficiency—all while ensuring the safety of employees and inventory. The Heavy Duty Pipe Storage Rack with Crank-Out Cantilever Design is engineered to meet these demands, combining heavy-duty construction with intuitive crank-out functionality to provide a reliable storage solution for the most demanding industrial applications.

When it comes to storing heavy, long materials like steel pipes, bars, and tubes, a one-size-fits-all storage solution simply won’t cut it. Industrial facilities require a storage system that offers exceptional strength, easy accessibility, and space efficiency—all while ensuring the safety of employees and inventory. The Heavy Duty Pipe Storage Rack with Crank-Out Cantilever Design is engineered to meet these demands, combining heavy-duty construction with intuitive crank-out functionality to provide a reliable storage solution for the most demanding industrial applications.

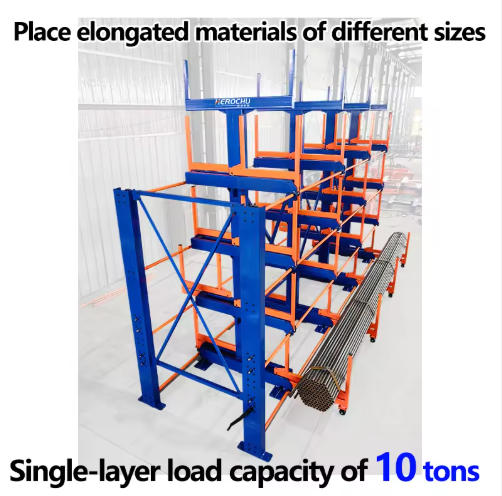

The defining feature of this rack is its heavy-duty construction, which is built to handle the weight of even the largest steel pipes. Constructed from high-strength carbon steel, the rack features thickened columns, reinforced cantilever arms, and precise welding techniques that ensure maximum stability and load-bearing capacity. Each layer can support up to 5000kgs, with total rack load capacities ranging from 8tons to 27tons depending on the configuration. This industrial-grade strength makes the rack suitable for use in manufacturing plants, construction sites, metal fabrication shops, and other facilities where heavy material storage is essential.

Accessibility is made easy with the rack’s crank-out cantilever design. Unlike fixed cantilever racks where materials at the back are difficult to reach, this system allows each layer to be fully extended—providing 100% access to every item stored. The crank-out mechanism is simple to operate, requiring only a single person to extend or retract the layers with a turn of the handle. High-precision ball bearing guide rails ensure smooth sliding, even when the layers are fully loaded, making material retrieval quick and effortless. This eliminates the need for costly forklifts or additional labor, reducing operational costs and improving efficiency.

Space optimization is a critical advantage of the Heavy Duty Pipe Storage Rack. By allowing materials to be handled directly by a crane, the rack eliminates the need for wide aisles that are typically required for forklift maneuvering. This means more of your warehouse space can be dedicated to storage, increasing your overall storage capacity without expanding your facility. The rack’s vertical design also maximizes height utilization, with configurable options up to 20 feet and multiple layers available—further enhancing space efficiency. Whether you’re working with a small workshop or a large warehouse, this design helps you make the most of your available space.

Safety is a top priority in any industrial setting, and this crank-out cantilever rack is equipped with several features to minimize risks. A manual lock mechanism prevents multiple layers from being extended simultaneously, reducing the risk of the rack tipping or materials falling. Sliding-type guide rails and foot rolling protection devices add an extra layer of safety by preventing accidental sliding or overturning of the layers. Additionally, the organized storage system eliminates the dangers of unsafe stacking or burying of materials, reducing the risk of injuries caused by falling items or unstable piles. By keeping materials neatly organized and easily accessible, this rack creates a safer workplace for your employees.

Versatility is another key benefit of the Heavy Duty Pipe Storage Rack, with a wide range of customizable configurations to meet your specific needs. Single or double units are available, and dimensions such as storage sheet size (6000mm, 9000mm, 12000mm, or custom), arm length (550mm to 800mm, or custom), distance between layers (600mm to 800mm, or custom), and number of layers can be tailored to your requirements. The rack is also available in orange or blue color options, allowing you to match it to your warehouse’s safety color-coding system. For facilities seeking even greater efficiency, electrically driven roll-out racking is available as an option, automating the extension process.

The Heavy Duty Pipe Storage Rack is designed to streamline material handling workflows, saving time and improving productivity. Materials can be moved directly from the rack to the terminal using a crane, eliminating intermediate handling steps and reducing downtime. The ability to organize materials by category, size, or project ensures that your team can quickly locate and retrieve the items they need, reducing search time and improving overall efficiency. Additionally, the rack’s low-maintenance design means less time spent on upkeep and more time focused on core operations—saving you both time and money in the long run.

Whether you’re storing steel pipes, aluminum bars, PVC tubes, or other long, heavy materials, the Heavy Duty Pipe Storage Rack with Crank-Out Cantilever Design provides a reliable, efficient, and safe storage solution. Its industrial-grade strength, 100% extendable layers, space-saving design, and customizable configurations make it an ideal choice for businesses looking to optimize their material storage operations. Invest in this high-performance rack today and experience the benefits of improved accessibility, increased storage capacity, enhanced safety, and reduced operational costs. Transform your warehouse into a more efficient, productive space with the Heavy Duty Pipe Storage Rack.

Factory

Hot Selling Machines

-

Heavy Duty Sheet Metal Storage Racks

Intelligent Production Line CNC Automated Storage Rack: Precision Meets Automation

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drawer-Style Sliding Sheet Metal Storage Rack – Efficient & Safe Material Handling

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Design for Steel Plate Storage with Heavy Duty Drawer Type Sheet Metal Rack Storage System

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Rack for Heavy Plates and Molds: Durable, Efficient Storage for Industrial Applications

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drive-In Pallet Rack Alternative: Space-Saving Drawer-Type Sheet Metal Storage with Automated Retrieval Compatibility

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Drawer Type Plate Shelves Warehouse Rack System for Industrial Metal Storage – 3-Ton Capacity per Layer

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Warehouse Storage System: Customizable Solutions for Metal Plate & Industrial Storage

Read moreRated 0 out of 5 -

Automated Storage Systems

Smart Fixed Profile Stereo Warehouse: Cost-Effective Automation for Small to Mid-Sized Fabrication Shops

Read moreRated 0 out of 5

Related products

Related products

-

Heavy Duty Cantilever Racking System

Innovative Pipe Storage Rack & Steel Cantilever Storage Rack System: Organize Long Materials Efficiently

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Telescopic Heavy-Duty Cantilever Rack for Long-Tube Storage

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Roll Out Cantilever Racking & Telesscopic Cantilever Pipe Rack

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Steel Tube Storage Racks & Cantilever Racks

Read moreRated 0 out of 5