Automatic Loading and Unloading System for Fiber Laser Cutting Machine

In the fast-paced world of sheet metal processing, efficiency and precision are the cornerstones of success. Manufacturers are constantly seeking solutions to minimize downtime, reduce labor costs, and maximize the utilization of their equipment. One such game-changing solution is the Automatic Loading and Unloading System for Fiber Laser Cutting Machine—a integrated setup that transforms traditional laser cutting operations into fully automated, unmanned production units. This system is not just a mere add-on; it is a complete ecosystem designed to streamline every step of the sheet metal processing workflow, from material storage to finished product handling.

In the fast-paced world of sheet metal processing, efficiency and precision are the cornerstones of success. Manufacturers are constantly seeking solutions to minimize downtime, reduce labor costs, and maximize the utilization of their equipment. One such game-changing solution is the Automatic Loading and Unloading System for Fiber Laser Cutting Machine—a integrated setup that transforms traditional laser cutting operations into fully automated, unmanned production units. This system is not just a mere add-on; it is a complete ecosystem designed to streamline every step of the sheet metal processing workflow, from material storage to finished product handling.

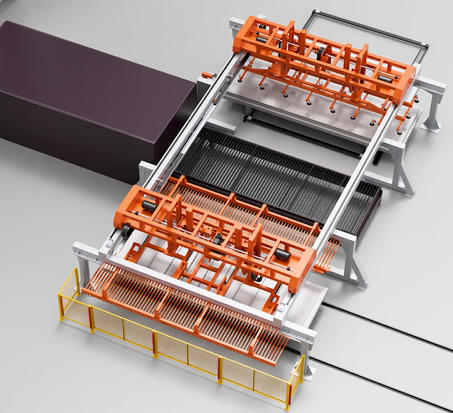

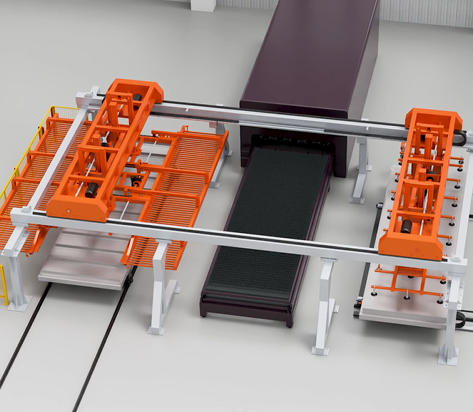

At the core of this system lies a carefully curated combination of components, each playing a vital role in ensuring seamless operation. It comprises a set of three-dimensional storage warehouse, a double-sided gantry truss, a loading truss manipulator, an unloading truss manipulator, a double-layer finished material truck, a PLC control system, and, of course, the fiber laser cutting machine itself. Together, these components form a cohesive sheet metal automatic production unit that eliminates the need for manual intervention at every critical stage.

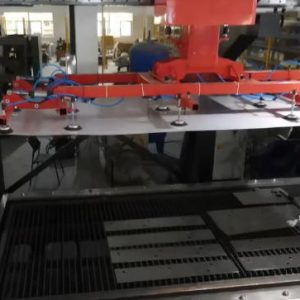

One of the most significant advantages of this system is its ability to maximize the productive time of fiber laser cutting machines, including popular models like Fiber Laser Fly Speed, Fly Pro, Wind, and Mach. By providing an uninterrupted material flow, it ensures that the laser cutting machine never sits idle waiting for raw materials or for finished sheets to be removed. The combination loading and unloading device is a key feature here: it uses suction cups to load raw material onto the cutting table and rakes to remove finished sheets once the cutting process is complete. This dual functionality not only saves time but also ensures gentle handling of the material, preventing damage that can occur with manual handling.

The speed of material exchange is another standout feature. With a rapid 65-second material exchange time, there is no wasted time between cutting cycles. This means that the laser cutting machine can operate continuously, significantly increasing the number of parts produced in a given period. For manufacturers dealing with high-volume orders, this translates directly to higher revenue and a competitive edge in the market. Moreover, the automatic operation of the system enables long periods of unmanned operation. This is particularly beneficial for businesses looking to extend their production hours beyond regular working shifts—whether it’s overnight, on weekends, or during holidays. With the system in place, manufacturers can achieve 24/7 production without the need to hire additional staff, reducing labor costs while boosting output.

Storage is often a pain point in sheet metal processing facilities, but the Automatic Loading and Unloading System addresses this issue effectively. The addition of a three-dimensional storage warehouse provides increased storage capacity, allowing manufacturers to keep a large inventory of raw materials on hand without taking up excessive floor space. The storage warehouse comes in various specifications to accommodate different sheet sizes, including 3015mm, 4015mm, 4020mm, 6015mm, 6020mm, and 6025mm. It also offers flexibility in terms of the number of floors, ranging from 8 to 13, and load capacity per layer—either 3T or 5T. The maximum load capacity of the system ranges from 300KG to 3000KG, making it suitable for handling a wide range of sheet metal materials, from thin aluminum sheets to thick steel plates.

To ensure smooth operation, the system has specific air consumption and air source requirements. It consumes 1.5m³ of air per minute and requires an air source pressure of 0.6-0.7Mpa. These parameters are carefully calibrated to ensure that the suction cups and other pneumatic components function reliably, providing a secure grip on the material during loading and unloading. The PLC control system acts as the brain of the operation, coordinating all the components to work in perfect harmony. It allows for easy programming of production schedules, monitoring of system status, and troubleshooting of any issues that may arise.

In addition to boosting productivity and reducing labor costs, the Automatic Loading and Unloading System for Fiber Laser Cutting Machine also enhances the quality of the finished products. Manual handling of sheet metal can lead to scratches, dents, or misalignment, which can affect the precision of the cuts and the overall quality of the parts. By eliminating manual intervention, the system ensures that the material is handled with consistent care, resulting in cleaner cuts and fewer defects. This not only improves customer satisfaction but also reduces the number of rejected parts, saving both time and money.

Another key benefit of the system is its scalability. As a business grows and its production needs increase, the system can be easily expanded to accommodate higher volumes. For example, additional storage floors can be added to the three-dimensional warehouse, or extra loading and unloading devices can be integrated to handle more cutting machines. This scalability ensures that the system remains a valuable asset for years to come, adapting to the changing needs of the business.

In conclusion, the Automatic Loading and Unloading System for Fiber Laser Cutting Machine is a must-have solution for any sheet metal processing facility looking to improve efficiency, reduce costs, and enhance product quality. Its integrated design, fast material exchange time, increased storage capacity, and ability to enable unmanned operation make it a powerful tool for boosting productivity. Whether you’re a small shop dealing with moderate volumes or a large manufacturer with high-volume orders, this system has the flexibility and capabilities to meet your needs. By investing in this system, you’re not just upgrading your equipment—you’re investing in the future success of your business.

Factory

Hot Selling Machines

-

Heavy Duty Sheet Metal Storage Racks

Intelligent Production Line CNC Automated Storage Rack: Precision Meets Automation

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drawer-Style Sliding Sheet Metal Storage Rack – Efficient & Safe Material Handling

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Design for Steel Plate Storage with Heavy Duty Drawer Type Sheet Metal Rack Storage System

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Rack for Heavy Plates and Molds: Durable, Efficient Storage for Industrial Applications

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drive-In Pallet Rack Alternative: Space-Saving Drawer-Type Sheet Metal Storage with Automated Retrieval Compatibility

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Drawer Type Plate Shelves Warehouse Rack System for Industrial Metal Storage – 3-Ton Capacity per Layer

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Warehouse Storage System: Customizable Solutions for Metal Plate & Industrial Storage

Read moreRated 0 out of 5 -

Automated Storage Systems

Smart Fixed Profile Stereo Warehouse: Cost-Effective Automation for Small to Mid-Sized Fabrication Shops

Read moreRated 0 out of 5

Related products

Related products

-

Sheet Metal Handling Equipment

Heavy-Duty Rotary Loading Robot for 100KG/200KG/300KG – The Ultimate Solution for Industrial Plate Handling

Read moreRated 0 out of 5