Automatic Storage System Steel Metal Plate Gantry Loading Unloading Robot Manipulator

In today’s competitive metal fabrication industry, efficiency, safety, and precision are no longer optional—they’re essential. Manual handling of heavy steel plates not only slows down production but also exposes workers to significant injury risks and material damage. The Automatic Storage System Steel Metal Plate Gantry Loading Unloading Robot Manipulator is engineered to solve these challenges by integrating intelligent automation directly into the heart of your sheet metal workflow.

Automatic Storage System Steel Metal Plate Gantry Loading Unloading Robot Manipulator – Precision Automation for Modern Fabrication

In today’s competitive metal fabrication industry, efficiency, safety, and precision are no longer optional—they’re essential. Manual handling of heavy steel plates not only slows down production but also exposes workers to significant injury risks and material damage. The Automatic Storage System Steel Metal Plate Gantry Loading Unloading Robot Manipulator is engineered to solve these challenges by integrating intelligent automation directly into the heart of your sheet metal workflow.

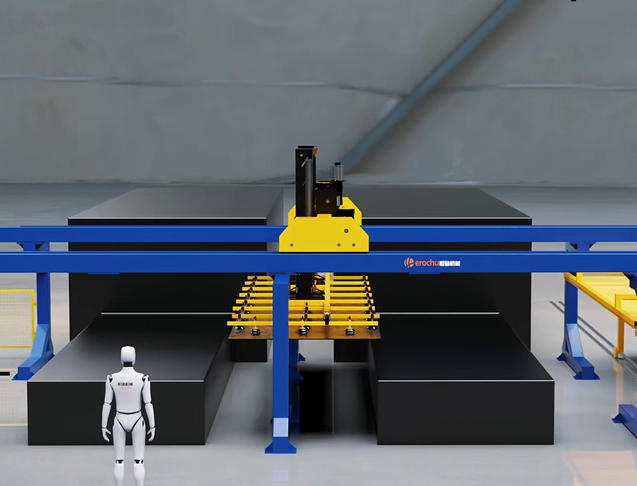

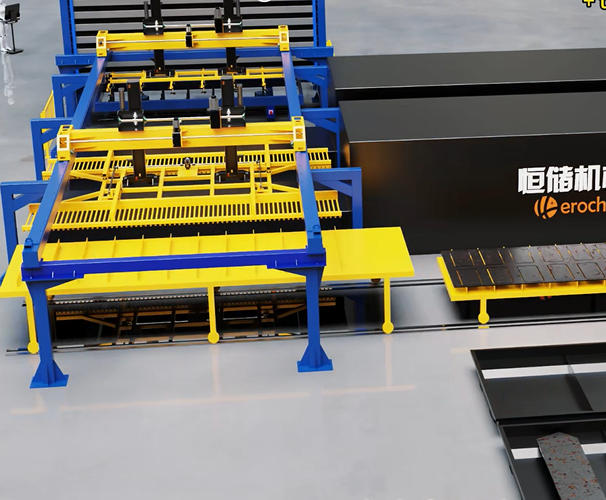

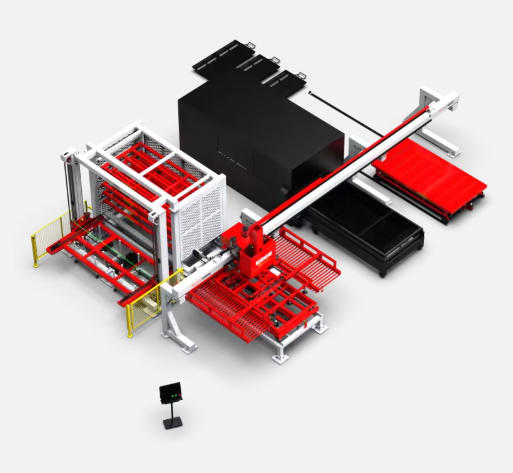

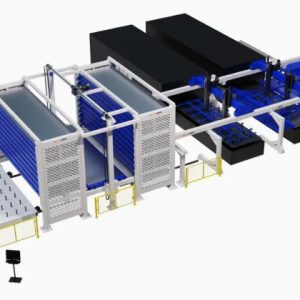

This advanced system combines a three-dimensional automated storage warehouse, dual gantry truss structures, dedicated loading and unloading manipulators, a double-layer finished material cart, a robust PLC control system, and seamless integration with laser cutting machines. Together, these components create a fully synchronized production cell that minimizes human intervention while maximizing throughput and consistency.

At the core of the system is its robotic manipulator—designed specifically for handling large, heavy steel plates ranging from 3015mm to 6025mm in size. Each manipulator uses a pneumatic rotating structure that enables 90-degree plate rotation, allowing it to adapt instantly to both transverse and longitudinal feeding requirements. This flexibility is critical in high-mix environments where job specifications change frequently, eliminating the need for manual reorientation or secondary handling.

The manipulator is equipped with a vacuum suction cup system using premium-brand components known for reliability and durability. Each suction cup can be independently controlled via the operator interface, and their relative positions are adjustable within a defined range to accommodate varying plate dimensions and weight distributions. This granular control ensures secure gripping—even on oily, uneven, or perforated surfaces—while preventing slippage or surface marring. Safety interlocks monitor vacuum pressure in real time, halting operation if grip integrity is compromised.

Movement is powered by a high-speed variable frequency motor, delivering rapid travel along linear guide rails with chain-driven transmission. The system achieves an impressive vertical lifting speed of 9 meters per minute and inlet/outlet speeds of 12 meters per minute, ensuring minimal cycle times between storage, processing, and staging. With 8 to 13 storage floors and a load capacity of 3 to 5 tons per layer, the 3D warehouse can hold substantial inventory vertically—freeing up valuable floor space previously consumed by static racks or staging areas.

One of the standout features is the system’s user-centric control architecture. Operators manage the entire workflow through a touchscreen HMI (Human-Machine Interface) located near the laser cutting stations. From this panel, they can switch between automatic and manual feeding modes in seconds—ideal for troubleshooting, maintenance, or low-volume custom jobs. Additionally, users can toggle between two laser cutting machines, directing the manipulator to feed whichever unit is ready, thereby balancing workload and preventing bottlenecks.

All system parameters—speed profiles, suction activation, rotation angles, and storage coordinates—are fully configurable via the same interface. Real-time monitoring, diagnostics, and error logging simplify troubleshooting, while remote access capabilities (optional) allow technicians to support operations without being onsite. Despite its sophistication, the system’s mechanical design remains simple and modular, resulting in low maintenance costs and easy component replacement when needed.

Safety is embedded at every level. By removing operators from direct contact with moving plates and heavy machinery, the system drastically reduces risks of crush injuries, strains, and repetitive motion disorders. The enclosed gantry structure also limits access to hazardous zones, complying with international safety standards such as ISO 13849 and ANSI B11.

From a productivity standpoint, the impact is measurable. Shops report 30–50% reductions in labor intensity, 20–40% faster job turnaround, and near-elimination of plate damage during handling. For businesses running multiple shifts or operating under tight delivery windows, these gains translate directly into higher capacity utilization and customer satisfaction.

Moreover, the system supports lean manufacturing principles. Just-in-time material delivery reduces work-in-progress inventory, while digital tracking ensures full traceability from raw stock to finished part. Integration with factory MES or ERP systems (via standard protocols like Modbus TCP or PROFINET) enables data-driven decision-making and predictive maintenance.

In summary, the Automatic Storage System Steel Metal Plate Gantry Loading Unloading Robot Manipulator is more than a piece of equipment—it’s a strategic investment in operational excellence. It bridges the gap between traditional fabrication and Industry 4.0 readiness, offering scalability, safety, and smart automation without unnecessary complexity. For fabricators seeking to future-proof their operations while cutting costs and improving quality, this system represents the new gold standard in automated material handling.

Factory

Hot Selling Machines

-

Heavy Duty Sheet Metal Storage Racks

Intelligent Production Line CNC Automated Storage Rack: Precision Meets Automation

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drawer-Style Sliding Sheet Metal Storage Rack – Efficient & Safe Material Handling

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Design for Steel Plate Storage with Heavy Duty Drawer Type Sheet Metal Rack Storage System

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Rack for Heavy Plates and Molds: Durable, Efficient Storage for Industrial Applications

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drive-In Pallet Rack Alternative: Space-Saving Drawer-Type Sheet Metal Storage with Automated Retrieval Compatibility

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Drawer Type Plate Shelves Warehouse Rack System for Industrial Metal Storage – 3-Ton Capacity per Layer

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Warehouse Storage System: Customizable Solutions for Metal Plate & Industrial Storage

Read moreRated 0 out of 5 -

Automated Storage Systems

Smart Fixed Profile Stereo Warehouse: Cost-Effective Automation for Small to Mid-Sized Fabrication Shops

Read moreRated 0 out of 5

Related products

Related products

-

Sheet Metal Handling Equipment

Gantry Robot Auto Load System for Laser Cutter

Read moreRated 0 out of 5 -

Sheet Metal Handling Equipment

Automatic Loading and Unloading Systems for Fiber Laser Cutting Machines

Read moreRated 0 out of 5