Intelligent Production Line CNC Automated Storage Rack: Precision Meets Automation

Every component of our Intelligent Production Line CNC Automated Storage Rack undergoes rigorous finite element stress analysis using industry-leading software like Simsolid and Ansys. This sophisticated engineering process ensures:

- Precise strength verification calculations: for all structural elements

- Optimized load distribution: across the entire system

- Enhanced durability: through meticulous engineering

- Customized performance characteristics: tailored to specific CNC applications

These engineering practices guarantee that our systems deliver reliable performance under real-world operational conditions, meeting the exacting standards of precision manufacturing.

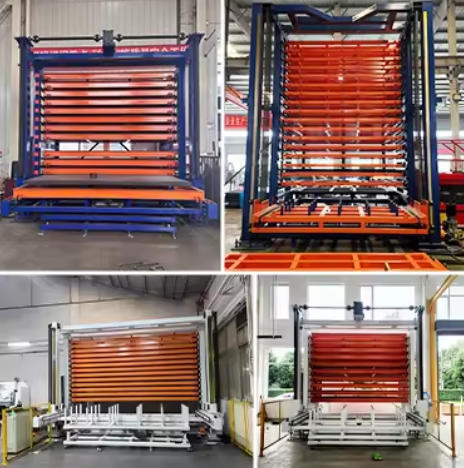

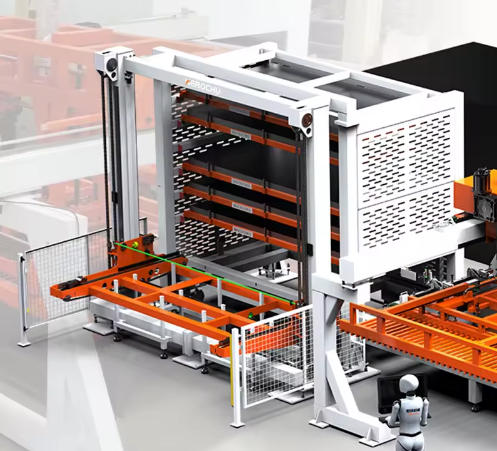

The Intelligent Production Line CNC Automated Storage Rack represents the pinnacle of material handling innovation, combining precision CNC technology with advanced automation to create a seamless production environment. This system is designed to meet the exacting demands of modern manufacturing, where precision and efficiency are paramount.

Advanced Engineering Through Finite Element Analysis

Every component of our Intelligent Production Line CNC Automated Storage Rack undergoes rigorous finite element stress analysis using industry-leading software like Simsolid and Ansys. This sophisticated engineering process ensures:

- Precise strength verification calculations: for all structural elements

- Optimized load distribution: across the entire system

- Enhanced durability: through meticulous engineering

- Customized performance characteristics: tailored to specific CNC applications

These engineering practices guarantee that our systems deliver reliable performance under real-world operational conditions, meeting the exacting standards of precision manufacturing.

Perfect Integration with CNC Production Lines

The true innovation of our Intelligent Production Line CNC Automated Storage Rack lies in its perfect integration with CNC machining technology:

- Precision material positioning: ensuring accurate machining every time

- Automatic tooling integration: for seamless operation

- Uninterrupted material supply: during production cycles

- Enhanced safety: by removing workers from hazardous areas

- Improved machining quality: through consistent material positioning

This integration creates a closed-loop production system where material handling and machining operations work in perfect harmony, maximizing efficiency and minimizing downtime.

Customization Options for CNC Applications

We understand that CNC production environments have unique requirements. That’s why we offer extensive customization options for our Intelligent Production Line CNC Automated Storage Rack:

- Customized Layers: configurations from 8 to 13 floors available

- Customized load-bearing capacity: single shelves support 1-6 tons

- Custom color options: to match facility aesthetics

- Plate Support: optional enhancement for specific materials

- System configuration: tailored to available space and CNC layout

These customization capabilities ensure seamless integration with your existing CNC operations, whether you’re in automotive manufacturing, aerospace, or precision machining.

Space Optimization Through Three-Dimensional Design

Our system incorporates innovative three-dimensional storage design to maximize space utilization in CNC environments:

- 200% increase in material storage capacity: compared to traditional methods

- Vertical space utilization: minimizes required floor area near CNC machines

- Flexible configurations: adapt to available space constraints

- Future expansion capability: without major facility modifications

This space-saving innovation is particularly valuable for urban CNC facilities or those with limited real estate options near production areas.

Automated Material Handling: Precision Without Human Intervention

The system incorporates advanced automation technologies to eliminate manual material handling entirely:

- High-precision robotic arms: for accurate material placement

- AGV transfer systems: for seamless material movement

- Single material retrieval time ≤ 10 seconds: dramatically faster than manual methods

- 24/7 operation capability: without concerns for worker availability

- Consistent performance: eliminating human error variability

These automated features ensure smooth operation even in high-volume CNC production environments.

Smart Inventory Management Through IoT Integration

Modern CNC production requires real-time visibility into inventory levels. Our solutions address this need through:

- IoT sensor network: for continuous material quantity monitoring

- Automatic replenishment alerts: preventing production delays

- Inventory turnover rate improvement: up to 60% increase

- Data-driven decision making: through real-time analytics

These smart features transform your material handling system into an active participant in your CNC production process.

Comprehensive Material Tracking System

For traceability and efficiency in CNC environments, we implement an RFID-based tracking system where:

- Each board is labeled with an RFID tag

- The entire material lifecycle is recorded digitally

- Real-time data on material location and status is available

- Comprehensive audit trails for quality control

- Enhanced inventory accuracy

This system provides complete visibility into your material inventory at all times, critical for maintaining quality standards in CNC machining.

Why Choose Our Intelligent Production Line CNC Automated Storage Rack?

End-to-End Service Support

We offer comprehensive support throughout the entire lifecycle of your system:

- Free design drawings: tailored to your specific requirements

- On-site installation: by our experienced technicians

- Professional after-sales team: for ongoing support

- Exclusive one-on-one service: ensuring your success

Rigorous Quality Assurance Process

Quality is embedded in every aspect of our manufacturing process:

- Dedicated quality inspection team: conducts item-by-item inspections

- Every screw and interface checked: multiple times for verification

- Strict quality control standards: as the absolute minimum requirement

- Comprehensive testing records: maintained for every batch

- Traceability system: for any quality issues

Pre-Shipment Quality Verification

Before any product leaves our facility:

- Multiple inspection processes: ensure product integrity

Factory

Hot Selling Machines

-

Heavy Duty Sheet Metal Storage Racks

Intelligent Production Line CNC Automated Storage Rack: Precision Meets Automation

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drawer-Style Sliding Sheet Metal Storage Rack – Efficient & Safe Material Handling

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Design for Steel Plate Storage with Heavy Duty Drawer Type Sheet Metal Rack Storage System

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Rack for Heavy Plates and Molds: Durable, Efficient Storage for Industrial Applications

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drive-In Pallet Rack Alternative: Space-Saving Drawer-Type Sheet Metal Storage with Automated Retrieval Compatibility

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Drawer Type Plate Shelves Warehouse Rack System for Industrial Metal Storage – 3-Ton Capacity per Layer

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Warehouse Storage System: Customizable Solutions for Metal Plate & Industrial Storage

Read moreRated 0 out of 5 -

Automated Storage Systems

Smart Fixed Profile Stereo Warehouse: Cost-Effective Automation for Small to Mid-Sized Fabrication Shops

Read moreRated 0 out of 5

Related products

Related products

-

Heavy Duty Sheet Metal Storage Racks

Heavy Duty Forklift steel plates Storage Rack

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy Duty Shelves Built for Sheet Metal—Not Afterthoughts

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy Duty Steel Sheets Storage Racks

Read moreRated 0 out of 5