Metal Sheet Warehouse Rack Solution

In industrial environments where floor space comes at a premium, the metal sheet warehouse rack system represents a paradigm shift in material storage efficiency. This innovative solution combines two distinct storage methods into a single, space-optimized unit, addressing the common challenge of storing large metal sheets while maintaining quick access and operational efficiency.

In industrial environments where floor space comes at a premium, the metal sheet warehouse rack system represents a paradigm shift in material storage efficiency. This innovative solution combines two distinct storage methods into a single, space-optimized unit, addressing the common challenge of storing large metal sheets while maintaining quick access and operational efficiency.

The Dual-Rack System Design

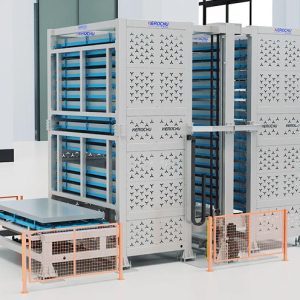

The metal sheet warehouse rack is ingeniously designed as a combination of two storage systems:

- Horizontal Roll-Out Drawer System (Lower Block): This section features multiple drawers on wheels that can be fully extended (100% roll-out) beyond the rack structure. Each drawer provides complete access to every metal sheet stored within, allowing for easy handling and transport to cutting or punching machines.

- Forklift-Accessible Cassette System (Upper Block): The upper section utilizes cassettes that can be safely retrieved and transported using a forklift. The design incorporates openings in the cassettes that allow forklift forks to engage without making contact with the metal sheets, preventing damage during transport.

This combination creates a super compact storage solution that maximizes vertical space utilization while maintaining horizontal accessibility.

Key Features and Benefits

Space Optimization

- Compact Footprint: The system requires significantly less floor space compared to traditional storage methods, making it ideal for facilities with limited square footage.

- Vertical Integration: By combining horizontal and vertical storage elements, the system achieves high storage density without compromising accessibility.

Material Accessibility

- 100% Accessible Drawers: Every metal sheet in the horizontal section is immediately available for transport, eliminating the need to shift multiple sheets to access those at the bottom.

- Forklift-Safe Cassettes: The upper section allows for quick retrieval of material using standard forklift equipment without risking sheet damage.

Operational Efficiency

- Single-Person Handling: Both storage systems are designed for easy operation by a single worker, reducing labor requirements.

- Time-Saving Design: The roll-out drawers and forklift cassettes significantly reduce material handling time compared to conventional storage methods.

Technical Specifications

General Characteristics

- Material: Steel construction for durability and load-bearing capacity

- Structure: Drawer-based design with smooth linear guide rails

- Type: Multi-level racking system

- Mobility: Adjustable height configurations

- Height Range: 5-15 meters (customizable)

- Weight: 500kg per unit (approx.)

- Development: New Type innovative design

- Serviceability: Common use industrial application

Customization Options

- Number of Layers: Fully customizable based on storage needs

- Color Options: Available in orange, blue, or customized colors

- Size Variations: Standard sizes include 3015, 4015, 4020, 6015, 6020, and 6025mm configurations

- Load Capacity: 3T or 5T per layer options

- Movement System: Linear guide rail + chain transmission

- Lifting Speeds: Vertical – 9m/min, Inlet/Outlet – 12m/min

Applications

This versatile storage solution is particularly well-suited for:

- Industrial Manufacturing Facilities: Where space optimization and quick material access are critical

- Metal Processing Plants: For storing various sheet metals including aluminum, galvanized steel, and stainless steel

- Tool Room Organization: Where precision storage of large sheet materials is required

- Warehouse Operations: Particularly in high-density storage environments

Why Choose this Storage Solution?

- Space Efficiency: The combination of horizontal and vertical storage elements provides maximum material storage in minimal floor space.

- Material Protection: Both storage methods protect metal sheets from damage during handling and transport.

- Operational Simplicity: Designed for easy use by a single operator, reducing labor costs and increasing productivity.

- Customizability: The system can be tailored to specific facility requirements, material types, and storage volumes.

- Time Savings: The efficient design minimizes material handling time, keeping operations running smoothly.

Implementation Considerations

When planning to implement this metal sheet warehouse rack system, consider:

- Available Vertical Space: Ensure ceiling height can accommodate the system’s full height range.

- Material Handling Equipment: Verify compatibility with existing forklift equipment for the upper cassette system.

- Workflow Integration: The system should be positioned to optimize material flow to processing areas.

- Future Expansion: Consider whether the system can be easily expanded or reconfigured as storage needs grow.

Conclusion

The metal sheet warehouse rack system represents a significant advancement in industrial material storage technology. By combining two effective storage methods into a single space-saving unit, it addresses the common challenges of limited floor space and material accessibility. The system’s design focus on operational efficiency, material protection, and customization options make it an ideal solution for various industrial applications where metal sheet storage is a critical operational component.

Factory

Hot Selling Machines

-

Heavy Duty Sheet Metal Storage Racks

Intelligent Production Line CNC Automated Storage Rack: Precision Meets Automation

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drawer-Style Sliding Sheet Metal Storage Rack – Efficient & Safe Material Handling

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Design for Steel Plate Storage with Heavy Duty Drawer Type Sheet Metal Rack Storage System

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Rack for Heavy Plates and Molds: Durable, Efficient Storage for Industrial Applications

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drive-In Pallet Rack Alternative: Space-Saving Drawer-Type Sheet Metal Storage with Automated Retrieval Compatibility

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Drawer Type Plate Shelves Warehouse Rack System for Industrial Metal Storage – 3-Ton Capacity per Layer

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Warehouse Storage System: Customizable Solutions for Metal Plate & Industrial Storage

Read moreRated 0 out of 5 -

Automated Storage Systems

Smart Fixed Profile Stereo Warehouse: Cost-Effective Automation for Small to Mid-Sized Fabrication Shops

Read moreRated 0 out of 5

Related products

Related products

-

Automation Sheet Metal Material Warehouse

Double-Tower Sheet Material Automated Storage and Retrieval System

Read moreRated 0 out of 5 -

Automation Sheet Metal Material Warehouse

Fully Automatic Vertical Profile Smart Storage Unit

Read moreRated 0 out of 5 -

Automation Sheet Metal Material Warehouse

Fully Automatic Smart Industrial Long Material Warehouse

Read moreRated 0 out of 5 -

Automation Sheet Metal Material Warehouse

Automated Vertical Storage for Bars and Tubes

Read moreRated 0 out of 5