Steel Plate Material Handling Equipment for Modern Manufacturing

Steel plate handling has traditionally been a labor-intensive process, requiring multiple workers to lift, position, and secure large, heavy sheets onto cutting tables or assembly lines. This not only slows production but also poses serious safety risks. Enter automated solutions like the Pneumatic Cantilever Loading Manipulator and its more advanced counterpart, the Servo Swing Arm Manipulator for Automated Material Handling, which have revolutionized how manufacturers manage raw materials.

In today’s fast-paced industrial landscape, efficiency, safety, and precision are non-negotiable. One of the most critical components in metal fabrication workflows is Steel Plate Material Handling Equipment—a category that includes advanced systems like the Servo Swing Arm Handling Manipulator. These machines are engineered to streamline operations involving heavy steel plates, reduce human error, and significantly cut down labor costs.

Steel plate handling has traditionally been a labor-intensive process, requiring multiple workers to lift, position, and secure large, heavy sheets onto cutting tables or assembly lines. This not only slows production but also poses serious safety risks. Enter automated solutions like the Pneumatic Cantilever Loading Manipulator and its more advanced counterpart, the Servo Swing Arm Manipulator for Automated Material Handling, which have revolutionized how manufacturers manage raw materials.

Why Choose Automated Steel Plate Handling?

Modern Steel Plate Material Handling Equipment integrates servo-driven motion control, vacuum suction technology, and intelligent positioning algorithms to handle plates ranging from 1mm to 20mm in thickness—with load capacities up to 1000kg. For example, models such as the HC-R4020-1000 from Herochu (originating in Shandong, China) can manage plates as large as 4000×2000mm while maintaining millimeter-level accuracy during placement on laser cutting tables.

These systems feature:

- Modular assembly structures for easy installation and maintenance

- Emergency stop mechanisms and automatic braking for operator safety

- Ergonomic designs that simplify operation and reduce fatigue

Moreover, the cantilever retractable design maximizes floor space utilization—a crucial advantage in crowded workshops. Unlike fixed shelving or manual cranes, these manipulators adapt dynamically to different material lengths, making them ideal not just for steel plates but also for pipes, profiles, and other long-stock items.

Integration with Laser Cutting Systems

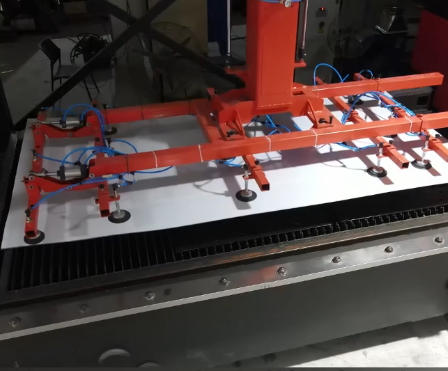

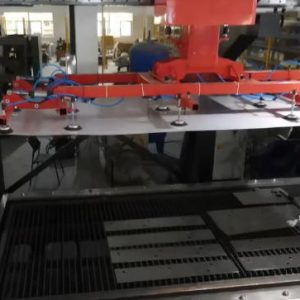

A primary application of this equipment is as a laser cutting loading machine. Positioned upstream of fiber or CO₂ laser cutters, the manipulator automatically transports steel plates from storage racks to the cutting bed. Using pre-programmed instructions, it identifies the plate’s dimensions and orientation, then places it precisely where needed—eliminating manual alignment and reducing setup time by up to 70%.

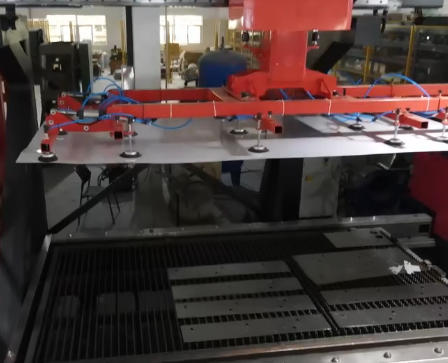

The gripping mechanism typically employs pneumatic or electric-powered suction cups (diameters from 150mm to 250mm), ensuring secure hold even on oily or slightly uneven surfaces. With 8 to 18 suction points depending on the model, stability is never compromised—even at maximum load.

Cost Efficiency and ROI

While the initial investment may seem significant, the return on investment (ROI) is rapid. By replacing 2–3 manual laborers per shift, companies reduce payroll expenses, minimize workplace injuries, and increase throughput. A single Servo Swing Arm Handling Manipulator can operate continuously for 16+ hours daily, supporting high-volume production without fatigue.

Additionally, with a standard 1-year warranty and robust construction (unit weight ~500kg), these machines offer long-term reliability. Their fully automatic operation type and compatibility with Industry 4.0 protocols make them future-proof assets in smart factories.

In conclusion, Steel Plate Material Handling Equipment—especially servo-driven swing arm manipulators—is no longer a luxury but a necessity for competitive metal fabrication. Whether you’re processing mild steel, stainless steel, or aluminum plates, integrating this technology ensures safer, faster, and more cost-effective operations.

Factory

Hot Selling Machines

-

Heavy Duty Sheet Metal Storage Racks

Intelligent Production Line CNC Automated Storage Rack: Precision Meets Automation

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drawer-Style Sliding Sheet Metal Storage Rack – Efficient & Safe Material Handling

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Design for Steel Plate Storage with Heavy Duty Drawer Type Sheet Metal Rack Storage System

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Rack for Heavy Plates and Molds: Durable, Efficient Storage for Industrial Applications

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drive-In Pallet Rack Alternative: Space-Saving Drawer-Type Sheet Metal Storage with Automated Retrieval Compatibility

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Drawer Type Plate Shelves Warehouse Rack System for Industrial Metal Storage – 3-Ton Capacity per Layer

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Warehouse Storage System: Customizable Solutions for Metal Plate & Industrial Storage

Read moreRated 0 out of 5 -

Automated Storage Systems

Smart Fixed Profile Stereo Warehouse: Cost-Effective Automation for Small to Mid-Sized Fabrication Shops

Read moreRated 0 out of 5

Related products

Related products

-

Sheet Metal Handling Equipment

Innovative Material Handling Solutions: The Servo Swing Arm Manipulator for CNC Operations

Read moreRated 0 out of 5