Ultimate Guide to Steel Cantilever Racking for Pipe and Long Material Storage

In industrial and warehouse settings, storing long, bulky, or irregularly shaped materials like pipes, beams, lumber, and metal strips can be challenging. Traditional shelving systems often struggle to accommodate these items efficiently, leading to wasted space, safety risks, and operational inefficiencies. Enter steel cantilever racking pipe storage systems—a revolutionary solution designed to maximize storage capacity while ensuring safety and flexibility.

In industrial and warehouse settings, storing long, bulky, or irregularly shaped materials like pipes, beams, lumber, and metal strips can be challenging. Traditional shelving systems often struggle to accommodate these items efficiently, leading to wasted space, safety risks, and operational inefficiencies. Enter steel cantilever racking pipe storage systems—a revolutionary solution designed to maximize storage capacity while ensuring safety and flexibility.

This article explores the benefits, specifications, and applications of cantilever racking, focusing on heavy-duty models such as the HC-G6053D, HC-G9055S, HC-G9055D, and HC-G12055D. Whether you’re managing construction materials, manufacturing components, or bulk inventory, cantilever racking provides a versatile and scalable solution.

Why Choose Cantilever Racking for Long Material Storage?

1. Optimized Space Utilization

Cantilever racks eliminate the need for traditional uprights or crossbars, allowing long items to extend beyond the frame. This design maximizes vertical and horizontal space, reducing clutter and improving accessibility. For example, pipes or lumber can be stored end-to-end without obstruction, significantly increasing storage density.

2. Enhanced Safety and Stability

Unlike conventional shelving, cantilever racking features double-layer anti-slip design and heavy-duty steel construction, ensuring robust stability even under extreme loads. The HC-G6053D model, for instance, supports 3 tons per layer with a 6-meter arm length, making it ideal for storing large-diameter pipes or metal beams without risk of collapse.

3. Flexibility for Irregularly Shaped Items

Cantilever racks are perfect for materials that don’t fit standard shelving dimensions. Whether you’re handling 8-meter steel beams, 12-meter aluminum strips, or unevenly cut lumber, these systems adapt effortlessly. The HC-G12055D model, with a 12-meter arm length, excels in storing extra-long goods while maintaining structural integrity.

4. Customizable Configurations

Every warehouse has unique storage needs. Cantilever racking systems offer adjustable layer heights, bilateral or unilateral assistance, and modular design, allowing seamless integration into existing layouts. For example, the HC-G9055D supports 5 tons per layer with 9-meter arms and bilateral support, making it suitable for high-density storage environments.

Key Specifications of Heavy-Duty Cantilever Racks

1. HC-G6053D – Compact and Efficient

- Load Capacity: 3 tons per layer

- Arm Length: 6 meters

- Layers: 4 + 1 (Bilateral assistance)

- Overall Dimensions: 6435 x 3340 x 1750 mm

- Ideal for: Small warehouses, construction sites, or facilities with limited space.

2. HC-G9055S – Unilateral Heavy-Duty Solution

- Load Capacity: 5 tons per layer

- Arm Length: 9 meters

- Layers: 4 + 1 (Unilateral assistance)

- Overall Dimensions: 9435 x 3340 x 1550 mm

- Ideal for: Facilities needing unilateral access, such as assembly lines or material staging areas.

3. HC-G9055D – Bilateral High-Capacity Racking

- Load Capacity: 5 tons per layer

- Arm Length: 9 meters

- Layers: 4 + 1 (Bilateral assistance)

- Overall Dimensions: 9435 x 3340 x 1750 mm

- Ideal for: Large warehouses or distribution centers requiring high-density storage on both sides.

4. HC-G12055D – Extra-Long Material Storage

- Load Capacity: 5 tons per layer

- Arm Length: 12 meters

- Layers: 4 + 1 (Bilateral assistance)

- Overall Dimensions: 12435 x 3340 x 1750 mm

- Ideal for: Manufacturing plants handling extremely long materials like steel pipes or structural beams.

Core Advantages of Cantilever Racking Systems

1. Extreme Load Capacity

- Up to 14,000 kg per upright side (KRS series), ensuring handling of even the heaviest industrial loads.

- Double-layer anti-slip design prevents material slippage, enhancing safety during loading/unloading.

2. Modular and Expandable Design

- Adjustable in 100 mm increments, allowing customization for varying material heights.

- Bolted uprights and base profiles ensure easy assembly and disassembly for relocation or expansion.

3. Versatile Applications

- Manual or electric operation options cater to different workflow needs.

- Stationary or mobile configurations support dynamic material handling environments.

4. Cost-Effective Installation

- Few components and simple assembly reduce setup time and labor costs.

- Matching accessories (e.g., safety barriers, locking mechanisms) enhance functionality without complexity.

How Cantilever Racking Enhances Warehouse Operations

1. Improved Material Accessibility

- No obstructions from uprights or crossbars, enabling forklifts or cranes to access materials directly.

- High visibility of stored items reduces search time and improves picking efficiency.

2. Enhanced Safety Protocols

- Robust construction minimizes risks of collapses or material damage.

- Anti-corrosion protection ensures longevity in harsh environments (e.g., outdoor storage or chemical exposure).

3. Scalability for Growing Needs

- Expandable design allows adding layers or arms as inventory grows.

- Retrofit options enable converting existing shelving into cantilever systems.

Choosing the Right Cantilever Rack for Your Needs

1. Assess Load Requirements

- Determine the weight per layer (e.g., 3 tons for HC-G6053D vs. 5 tons for HC-G9055D).

- Consider dynamic loads if materials will be moved frequently.

2. Evaluate Material Dimensions

- Measure the length and width of stored items to select appropriate arm lengths.

- Ensure the rack can accommodate irregular shapes (e.g., bent pipes or oversized lumber).

3. Optimize for Space Constraints

- Overall dimensions (e.g., 6435 x 3340 x 1750 mm for HC-G6053D) must fit within available floor space.

- Layer height adjustments allow customization for low-ceiling warehouses.

Conclusion

Cantilever racking systems are a game-changer for industries dealing with long, heavy, or irregularly shaped materials. From pipe storage racks to industrial lumber shelving, these solutions offer unmatched flexibility, safety, and efficiency. By selecting the right model—whether the HC-G6053D for compact spaces or the HC-G12055D for extra-long materials— businesses can transform their storage operations, reduce costs, and enhance productivity.

For expert guidance on customizing your cantilever racking system, contact our team today. Let us help you safely store long goods with pipe racks and unlock the full potential of your warehouse space!

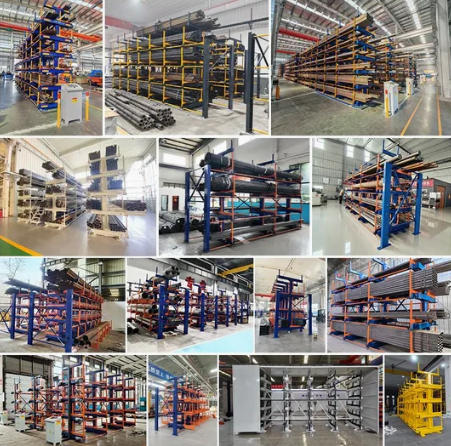

Factory

Hot Selling Machines

-

Heavy Duty Sheet Metal Storage Racks

Intelligent Production Line CNC Automated Storage Rack: Precision Meets Automation

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drawer-Style Sliding Sheet Metal Storage Rack – Efficient & Safe Material Handling

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Design for Steel Plate Storage with Heavy Duty Drawer Type Sheet Metal Rack Storage System

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Rack for Heavy Plates and Molds: Durable, Efficient Storage for Industrial Applications

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drive-In Pallet Rack Alternative: Space-Saving Drawer-Type Sheet Metal Storage with Automated Retrieval Compatibility

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Drawer Type Plate Shelves Warehouse Rack System for Industrial Metal Storage – 3-Ton Capacity per Layer

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Warehouse Storage System: Customizable Solutions for Metal Plate & Industrial Storage

Read moreRated 0 out of 5 -

Automated Storage Systems

Smart Fixed Profile Stereo Warehouse: Cost-Effective Automation for Small to Mid-Sized Fabrication Shops

Read moreRated 0 out of 5

Related products

Related products

-

Heavy Duty Cantilever Racking System

Advanced Telescopic Cantilever Storage Solutions of Industrial Storage

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Streamline Long-Material Handling with Roll-Out Telescopic Cantilever Rack Systems

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Telescopic Cantilever Pipe Racks for Modern Industrial Warehousing

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Drive-In Foldable Vertical Storage System – Space-Saving Innovation for Narrow Aisles

Read moreRated 0 out of 5