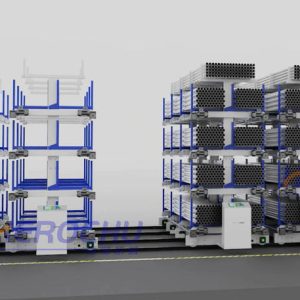

Roll Out Telescopic Cantilever Pipe Rack Systems

Roll out cantilever racks feature drawer-like compartments that can be fully extended for complete access to stored materials. The system typically includes:

- Sturdy metal arms mounted on rollers

- Smooth-gliding drawer mechanisms

- Locking pins for security

- Optional mechanical assists for easier operation

Roll Out Telescopic Cantilever Pipe Rack Systems

How Roll Out Racks Work

Roll out cantilever racks feature drawer-like compartments that can be fully extended for complete access to stored materials. The system typically includes:

- Sturdy metal arms mounted on rollers

- Smooth-gliding drawer mechanisms

- Locking pins for security

- Optional mechanical assists for easier operation

HC-G6053S – The Compact Powerhouse

Ideal for facilities with space constraints, the HC-G6053S offers:

- 6000mm storage sheet size

- 2-ton loading per layer

- 3+1 layer configuration

- Single-arm design

- Total loading capacity of 8 tons per rack

HC-G6053D – The High-Capacity Option

For heavier loads, the HC-G6053D features:

- 6000mm storage sheet size

- 3-ton loading per layer

- 4+1 layer configuration

- Double-arm design

- Impressive 25-ton total loading capacity

Large-Scale Pipe Storage Solutions

HC-G9055S – The Heavy-Duty Workhorse

Designed for substantial storage needs, the HC-G9055S provides:

- 9000mm storage sheet size

- 5-ton loading per layer

- 3+1 layer configuration

- Double-arm design

- 35-ton total loading capacity

HC-G9055D – The Maximum Capacity System

For facilities requiring enormous storage capacity, the HC-G9055D offers:

- 12000mm storage sheet size

- 6-ton loading per layer

- 3+1 layer configuration

- Double-arm design

- Massive 42-ton total loading capacity

Customized Storage Solutions

For unique requirements, customized options allow for:

- tailored dimensions

- specific load capacities

- specialized configurations

- color customization

- integration with existing warehouse systems

Technical Specifications and Features

Loading Capacities

Each model offers tiered loading capacities:

- HC-G6053S: 8 tons total

- HC-G6053D: 25 tons total

- HC-G9055S: 35 tons total

- HC-G9055D: 42 tons total

Physical Dimensions

- Arm length: 550mm (HC-G6053S), 600mm (HC-G6053D), 800mm (HC-G9055S & HC-G9055D)

- Distance between layers: 600mm (HC-G6053S & HC-G6053D), 800mm (HC-G9055S & HC-G9055D)

Operation System

All models feature:

- PLC frequency conversion control

- Smooth operation mechanism

- Optional motorized assistance available

Color Options

Standard color options include:

- Orange

- Blue

- Custom colors available upon request

Applications Across Industries

Manufacturing Facilities

- Storing raw materials

- Organizing work-in-progress inventory

- Staging finished products for shipment

Warehousing Operations

- Long-term storage solutions

- Distribution center organization

- Seasonal inventory management

Construction and Building Materials

- Pipe storage for plumbing and HVAC

- Steel profile storage for framing

- Drywall and lumber organization

Other Industrial Applications

- Automotive parts storage

- Aerospace component organization

- Agricultural equipment storage

Benefits of Implementing Pipe Storage Racks

Enhanced Operational Efficiency

- Faster material retrieval

- Reduced labor requirements

- Improved workflow organization

Significant Space Savings

- Vertical storage utilization

- Elimination of wasted space

- Ability to store more in less area

Improved Workplace Safety

- Elimination of material pile hazards

- Reduced risk of musculoskeletal injuries

- Better organization means fewer accidents

Easy Handling and Accessibility

- Roll-out drawer systems for complete access

- Ability to operate with minimal effort

- Tool-free adjustments for easy customization

Installation and Maintenance Considerations

Professional Installation

- Site assessment and planning

- Proper anchoring and leveling

- Safety inspections and certifications

Regular Maintenance

- Routine inspections of moving parts

- Lubrication of drawer mechanisms

- Structural integrity checks

- Safety feature verification

Troubleshooting Common Issues

- Drawer alignment problems

- Locking mechanism failures

- Wear and tear on rollers

- Arm deflection under load

Cost Analysis and ROI

Initial Investment Factors

- Rack system size and capacity

- Customization requirements

- Installation complexity

- Accessories and additional features

Long-Term Cost Savings

- Reduced labor costs

- Decreased material handling expenses

- Lower risk of costly accidents

- Improved inventory management

Calculating Return on Investment

- Space utilization metrics

- Operational efficiency improvements

- Accident reduction statistics

- Inventory management benefits

Future Trends in Pipe Storage Solutions

Smart Storage Systems

- IoT-enabled inventory tracking

- Automated retrieval systems

- Real-time data analytics

Sustainable Storage Solutions

- Eco-friendly materials

- Energy-efficient operation

- Recyclable components

Modular and Configurable Designs

- Adaptable to changing needs

- Scalable storage solutions

- Easy reconfiguration options

Conclusion

Summary of Key Points

- Heavy-duty pipe storage racks offer significant advantages over traditional methods

- Various models cater to different storage needs and space constraints

- Roll out cantilever systems provide unparalleled accessibility

- Custom solutions available for unique requirements

- Substantial benefits in efficiency, safety, and cost savings

Final Recommendations

- Assess your specific storage needs and constraints

- Consult with storage experts for optimal solutions

- Consider future growth when selecting systems

- prioritize safety and accessibility in your design

- Implement proper maintenance protocols for longevity

By implementing these advanced pipe storage solutions, industrial facilities can dramatically improve their operations, creating safer, more efficient work environments while maximizing their valuable storage space.

Factory

Hot Selling Machines

-

Heavy Duty Sheet Metal Storage Racks

Intelligent Production Line CNC Automated Storage Rack: Precision Meets Automation

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drawer-Style Sliding Sheet Metal Storage Rack – Efficient & Safe Material Handling

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Design for Steel Plate Storage with Heavy Duty Drawer Type Sheet Metal Rack Storage System

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Rack for Heavy Plates and Molds: Durable, Efficient Storage for Industrial Applications

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drive-In Pallet Rack Alternative: Space-Saving Drawer-Type Sheet Metal Storage with Automated Retrieval Compatibility

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Drawer Type Plate Shelves Warehouse Rack System for Industrial Metal Storage – 3-Ton Capacity per Layer

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Warehouse Storage System: Customizable Solutions for Metal Plate & Industrial Storage

Read moreRated 0 out of 5 -

Automated Storage Systems

Smart Fixed Profile Stereo Warehouse: Cost-Effective Automation for Small to Mid-Sized Fabrication Shops

Read moreRated 0 out of 5

Related products

Related products

-

Heavy Duty Cantilever Racking System

Roll-Out Telescopic Cantilever Rack for Streamlined Operations

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Innovative Pipe Storage Rack & Steel Cantilever Storage Rack System: Organize Long Materials Efficiently

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Rail Type Telescopic Cantilever Shelves for Profile Steel Pipe Storage

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Drive-In Foldable Vertical Storage System – Space-Saving Innovation for Narrow Aisles

Read moreRated 0 out of 5