Heavy-duty Drawer-type Sheet Rack – Intelligent Access for Industrial Efficiency

When precision, safety, and speed matter in sheet metal handling, the Heavy-duty Drawer-type Sheet Rack emerges as a game-changing storage innovation. Combining mechanical reliability with user-centric design, this system transforms how workshops and warehouses manage flat, bulky materials. No more precarious leaning stacks or time-consuming searches—every sheet is neatly housed in a fully extendable drawer, ready for immediate use.

When precision, safety, and speed matter in sheet metal handling, the Heavy-duty Drawer-type Sheet Rack emerges as a game-changing storage innovation. Combining mechanical reliability with user-centric design, this system transforms how workshops and warehouses manage flat, bulky materials. No more precarious leaning stacks or time-consuming searches—every sheet is neatly housed in a fully extendable drawer, ready for immediate use.

Engineered for industrial-grade performance, these drawer racks support individual layer capacities of up to 20 tons, making them suitable for everything from thin-gauge steel to thick structural plates. The drawers glide smoothly on heavy-duty rails, and optional electric drive systems enable effortless operation—even for the largest loads. This intelligent integration reduces physical strain on workers and accelerates material turnover, directly boosting production throughput.

The standard models—such as HC-B2015-62, HB-B3015-65, and HC-B6020-65—accommodate common plate dimensions, but true customization is where this system shines. Need to store 6000x1500mm aluminum sheets? Or perhaps irregularly sized composite panels? Our engineering team designs each unit based on your exact specifications, including base footprint, number of drawers, and loading method (manual, semi-automatic, or fully motorized).

A major benefit of the drawer-type configuration is 100% drawer extension. Unlike partial-slide systems that leave rear materials out of reach, our racks allow full access to every inch of storage space. This eliminates the “digging” problem common in traditional shelving and ensures consistent inventory visibility. Additionally, horizontal storage prevents warping, scratching, or edge damage—critical for maintaining material quality in high-tolerance applications like aerospace or automotive manufacturing.

Safety is equally prioritized. Each drawer includes integrated locking mechanisms and anti-tip features, while the frame structure is tested to exceed industry load standards. Facilities using these racks report fewer workplace incidents and lower insurance claims, proving that smart storage directly contributes to a safer environment.

Beyond functionality, these racks contribute to lean manufacturing principles. By organizing materials systematically, they reduce search time, minimize handling errors, and support just-in-time workflows. In an era where every second counts, the Heavy-duty Drawer-type Sheet Rack isn’t just storage—it’s a strategic asset that drives operational excellence.

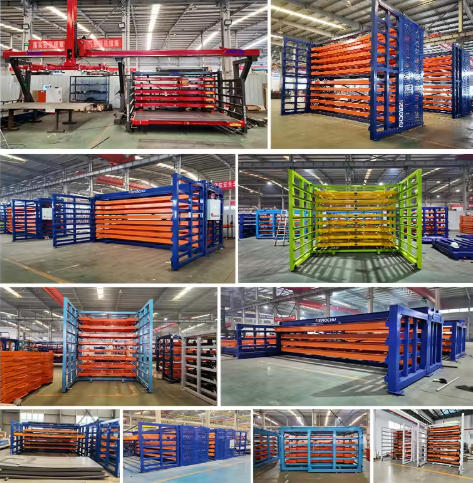

Factory

Hot Selling Machines

-

Heavy Duty Sheet Metal Storage Racks

Intelligent Production Line CNC Automated Storage Rack: Precision Meets Automation

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drawer-Style Sliding Sheet Metal Storage Rack – Efficient & Safe Material Handling

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Design for Steel Plate Storage with Heavy Duty Drawer Type Sheet Metal Rack Storage System

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Rack for Heavy Plates and Molds: Durable, Efficient Storage for Industrial Applications

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drive-In Pallet Rack Alternative: Space-Saving Drawer-Type Sheet Metal Storage with Automated Retrieval Compatibility

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Drawer Type Plate Shelves Warehouse Rack System for Industrial Metal Storage – 3-Ton Capacity per Layer

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Warehouse Storage System: Customizable Solutions for Metal Plate & Industrial Storage

Read moreRated 0 out of 5 -

Automated Storage Systems

Smart Fixed Profile Stereo Warehouse: Cost-Effective Automation for Small to Mid-Sized Fabrication Shops

Read moreRated 0 out of 5

Related products

Related products

-

Heavy Duty Sheet Metal Storage Racks

Heavy Duty Forklift Sheet Metal Storage Rack by Herochu

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sheet Metal Racking System That Works as Hard as Your Team

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy Duty Steel Sheets Storage Racks

Read moreRated 0 out of 5